Sign up for email alert when new content gets added: Sign up

Effect of hydrogen on mechanical properties of low strength steels in oil & gas applications

International Conference on oil and gas

August 05-06, 2019 | Singapore

Mimoun Elboujdaini

ACME, USA

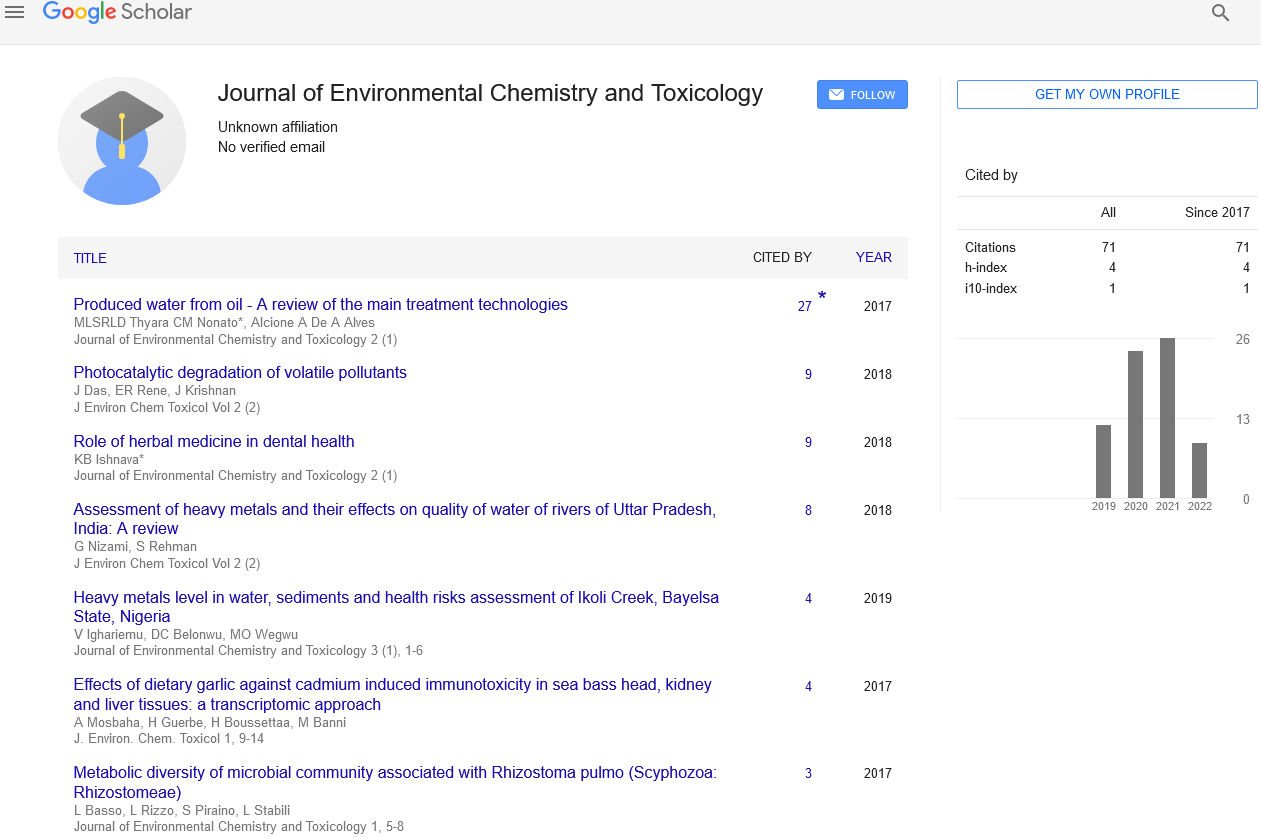

ScientificTracks Abstracts: J Environ Chem Toxicol

Abstract :

Hydrogen-induced cracking in steel & environmental cracking mechanisms is one of several related mechanisms whereby absorbed hydrogen atoms can compromise the integrity of components manufactured of low strength steels. This course principally addresses environmental embrittlement mechanisms active in sour gas production - i.e., occurrences in pipelines and pressure vessels handling sour gas and oil (upstream and downstream operations), gas transmission pipelines, etc. Sulphide Stress Cracking (SSC) is one of numerous “environmental embrittlement” mechanisms whereby a metal or alloy exposed to an aqueous or moist gaseous environment containing hydrogen sulphide (H2S) – a “sour environment” - can fail catastrophically.

The deleterious effects of hydrogen can be reduced or even eradicated through cautious selection of base metals, weld metals, and fabrication practices, as well as adherence to procedures. • Extent of the Problem: Occurrences in pipelines and pressure vessels handling sour gas and oil (upstream and downstream operations), gas transmission pipelines, etc.

• Mechanisms: Including the metallurgical and environmental conditions affecting the likelihood of HIC development. The related mechanism “Stress-Oriented Hydrogen-Induced Cracking” will also be described.

• Laboratory Testing Methods, and HIC-resistant steel purchase, quality assurance testing and acceptance criteria; e.g. HICresistance tests and steel specification, quality...etc.

• Metallurgical Control: New construction or replacement materials and specification of HIC-resistant steel.

• Environmental Control Options: Chemical inhibition, coatings, development of protective scales, etc. Understanding these factors is of great importance to minimize and control corrosion and material failure in many industrial applications as well as pipeline.

Understanding these factors is of great importance to minimize and control corrosion and material failure in many industrial applications as well as pipeline.

Biography :

Mimoun Elboujdaini is a Research Scientist with over 30 years in material R&D and management and coordinator of projects on engineering materials, their properties and performance in various service environments. The projects covered oil & gas, pipeline, aluminium base alloys, stainless steels, mining industry, and aerospace materials, etc. He is an Active member of several international professional societies as chairman and/or as member of Board of Directors. He is also Chaired several national and international conferences. He reviewed numerous papers for scientific journals, and acted as editor books, PhD thesis examiner and reviewer of graduate programs at the universities and Adjunct professorship at the University of Alberta. He has won several National & International awards and recognitions.

E-mail: melboujd@gmail.com