Denture Base Acrylic Materials

Received: 02-Nov-2022, Manuscript No. puldcr-23-6041 ; Editor assigned: 04-Nov-2022, Pre QC No. puldcr-23-6041 (PQ); Accepted Date: Nov 22, 2022; Reviewed: 18-Nov-2022 QC No. puldcr-23-6041 (Q); Revised: 21-Nov-2022, Manuscript No. puldcr-23-6041 (R); Published: 24-Nov-2022

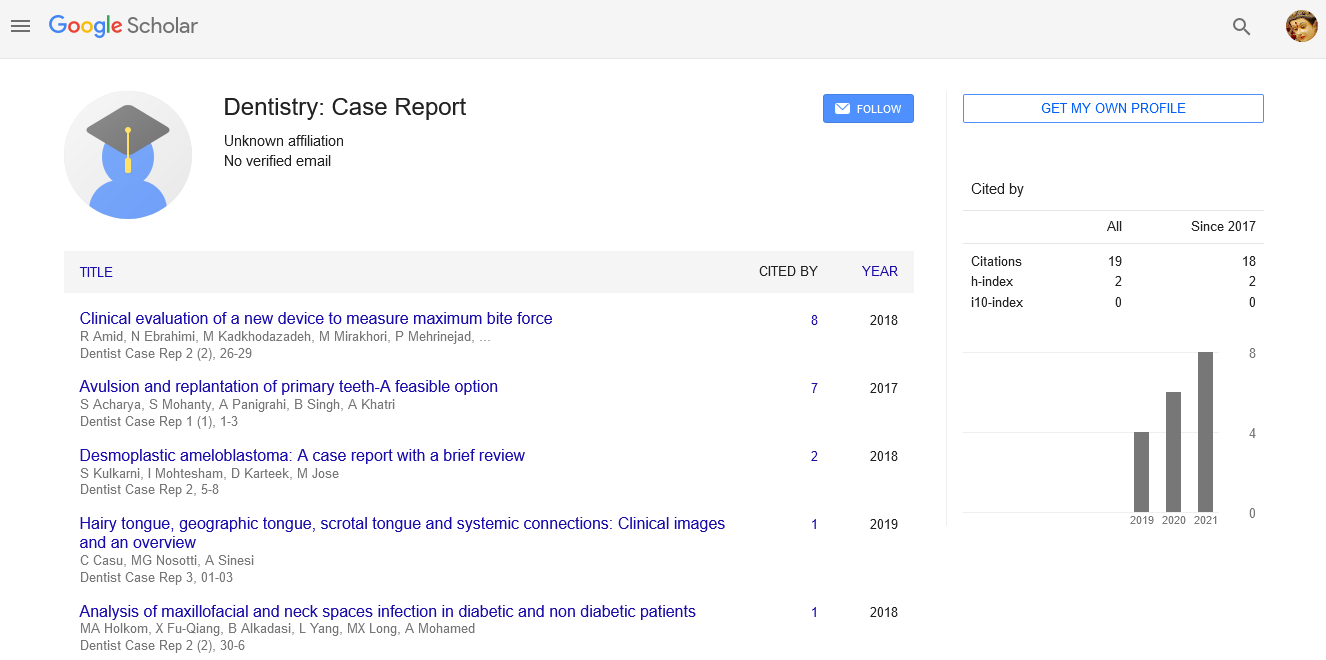

Citation: Pandey A. Denture base acrylic materials. Dent Case Rep. 2022; 6(6):6-8.

This open-access article is distributed under the terms of the Creative Commons Attribution Non-Commercial License (CC BY-NC) (http://creativecommons.org/licenses/by-nc/4.0/), which permits reuse, distribution and reproduction of the article, provided that the original work is properly cited and the reuse is restricted to noncommercial purposes. For commercial reuse, contact reprints@pulsus.com

Abstract

One of the most popular materials for the production of detachable dentures is heat-cured PMMA. Denture material that has been heat-cured contains soluble components that enable it to absorb and release chemicals. All of these elements have a direct impact on the durability and functionality of prostheses made from polymethyl methacrylate denture base material. It has been found that different processes used to create removable dentures from heat-cure denture base material have a considerable impact on the prosthesis's sorption and solubility.

Key Words

Cardiac rehabilitation; Core components; Guidelines; Heart valve surgery; Heart valve replacement

Introduction

Many people still prefer the heat-cured Polymethyl Methacrylate (PMMA) denture base material because of its good aesthetics, simplicity of manufacturing and repair, and relative affordability [1]. PMMA possesses a number of characteristics that make it an ideal base material for dentures, but there are downsides, including residual monomer toxicity, a high coefficient of thermal expansion, weak mechanical strength, and dimensional instability [1]. The resin's capacity to absorb water when exposed to a damp environment, which results in dimensional instability, is one of the main sources of PMMA acrylic's limits [2]

The release of unreacted monomer and other water-soluble byproducts from the denture base material during function may also cause an allergic reaction of the oral mucosa, therefore the sorption and solubility of denture base materials affect the material's mechanical qualities. The water sorption and solubility of denture base materials should be as low as feasible as a result. The user of the material can adjust a number of variables that can affect the sorption and solubility of the denture base material, including mixing ratios, polymerization cycles, the media in which the material is submerged, and surface treatments.

Goals and Objectives

High sorption readings could have a negative impact on a denture's mechanical characteristics and shorten its lifespan. According to Sakaguchi and Powers, sorption is a combination of adsorption and absorption [3]. While absorption is the passage of a substance into the body of a material, adsorption is the molecular adherence of a substance to the surface of a material. Sedimentation is the term used to describe the occurrence when both are occurring. Sorption is caused by the polarity of the PMMA molecules and happens when a denture base is exposed to a damp environment. Water molecules have an affinity for carbonyl groups, which are present in PMMA materials.

Water molecules adhere to the material's surface before being further absorbed into the denture base's body through porosity and diffusion into intermolecular gaps [2]. According to studies, water sorption adheres to Fick's law of diffusion, which is based on molecules moving from a high concentration to a low concentration. The density of the polymer network, the likelihood of hydrogen bonding, and the rate at which polar interactions can occur all affect how much and how quickly the material sorbs [4]. Water molecules fill the intermolecular spaces between the polymer chains as they permeate into the PMMA material's molecular structure. PMMA materials have weak secondary bonds, which makes it possible for water molecules to pull the polymer chains apart and cause the polymerized material to expand. Due to the small amount of open space available for water molecules to occupy inside the network's structure, polymers with a high cross-linking density have shown lower sorption values [4]. Water is sorbing into the PMMA structure in alternate directions. When a material is exposed to a dry, open atmosphere, it permits water to escape from its structure and experiences contraction. Internal tensions are created in the material as a result of this ongoing dimensional shift and the instability brought on by constant expansion and contraction, which may cause the denture to crack and craze. Dimensional instability may cause the development of surface fissures, which can serve as places of entry or adhesion for different bacteria, yeasts, and moulds. The plasticization of the denture base due to the interaction of water molecules with the PMMA polymer chains may also have an impact on the material's mechanical properties by lowering its hardness, fatigue limit, and transverse strength.

Solubility Of Base Material By-products

The biocompatibility of the prosthesis is directly impacted by the solubility of the denture base materials since high levels of diffusion may raise the risk of numerous cytotoxic consequences. It is crucial to lower the solubility of a prosthetic, and this point cannot be emphasised enough. The base material for PMMA dentures should be insoluble and have a molecular structure with good chemical and thermal stability [4].

Mixing Ratios

To attain the best results, PMMA denture base material manufacturers advise a variety of powder/liquid mixing ratios for their individual products. However, it is not unusual for dental laboratory personnel to modify these mixing ratios in an effort to alter the material's handling characteristics [5]. To increase the material's working time, more monomer can be added to the mixture. However, a higher monomer concentration can result in more residual monomer remaining in the material after polymerization. Extra monomer being added raises concerns since it may enhance the likelihood that patients would experience cytotoxic reactions to the denture base material while wearing them [6].

According to studies that looked at the sorption and solubility of different acrylic resins, heat-cured acrylic resins had lower solubility values than the majority of self-cured acrylic resins. Kosti et al. evaluated the residual monomer concentration found in dental acrylic polymers and its impact on tissue after implantation in a study that was identical to theirs [7].

Polymerisation Cycle

According to Anusavice et al., polymerization is "a chemical reaction in which chains of low-molecular-weight monomers are transformed into chains of high-molecular-weight polymers" [2]. A chemical component of the substance called an initiator causes the polymerization of denture base polymers. Depending on the substance, initiators respond when exposed to external trigger mechanisms like light or heat. The physical, mechanical, and biological aspects of the denture can be severely impacted by improper polymerization cycles, according to numerous research. Each manufacturer suggests a time- and temperature-oriented polymerization cycle for a particular material.

PMMA denture base material that has been heated up is polymerized through addition polymerization. According to Ouellette and Rawn, addition polymerization is a chain reaction in which one carboncarbon double bond is added to another [8]. When utilising heatactivated PMMA, the benzoyl peroxide initiator is activated by heating the mould containing the polymer-monomer mixture in a water bath. Free radicals are created when the benzoyl peroxide breaks down. The methyl methacrylate molecule's vinyl group is affected by the free radical's unpaired electron. The methyl methacrylate molecule's double bond is broken, causing the free radical to form a single bond with the monomer on one side and leaving the other free electron unpaired.

Surface Treatments

Surface treatments are used when working with denture base polymers to enhance the material's qualities and attributes, whether for physical, mechanical, chemical, or cosmetic reasons. Highly polished and smooth PMMA denture base surfaces encourage better gingival health, which benefits chewing efficiency, patient comfort, improved aesthetics, and prosthesis longevity. The traditional method of polishing is known as mechanical polishing, which uses abrasives of varied grits to change the surface of the material by smoothing off its texture or roughness. A different technique called chemical polishing can get to parts of the denture that mechanical polishing can't reach while also speeding up the overall polishing process. After finishing processes, the prosthesis is placed in a chemical polisher that contains heated methyl-methacrylate when chemical polishing is used. According to Rahal et al., heated methyl methacrylate polishing solvent penetrates the acrylic's surface polymeric chains and breaks the secondary bonds holding them together [5]. As a result, the acrylic resin eventually becomes plasticized.

Conclusion

The qualities of heat-cured PMMA, in particular its strength, dimensional stability, and biocompatibility, are adversely affected by the material's sorption and solubility. All of these elements have a direct impact on the prosthesis's durability, functionality, and comfort. Methods to lessen and regulate the degree of sorption and solubility encountered by heat-cured PMMA must play a significant role in the fabrication process to assure longterm function, especially for the elderly and those with lower incomes. While certain surface treatment techniques and storing the material in artificial saliva solution may improve the lifespan of the denture, mixing ratios and polymerization cycles have been identified as external variables that can negatively influence the rate of sorption and solubility experienced by denture base materials.

References

- Nandal S, Ghalaut P, Shekhawat H, et al. New era in denture base Resins: a review. Dent J Adv Stud. 2013;1(3):136–43. [Google Scholar] [Crossref]

- Anusavice KJ, Shen C, Rawls HR. Phillips’ Science of Dental Materials. Elsevier Health Sci. 2012;27. [Google Scholar]

- Sakaguchi RL, Powers JM. Testing of dental materials and biomechanics. Craig’s Restor. Dent. Mater. 2012;5:81-5. [Google Scholar]

- Ferracane JL. Hygroscopic and hydrolytic effects in dental polymer networks. Dent Mater. 2006;22(3):211–22. [Google Scholar] [Crossref]

- Rahal JS, Mesquita MF, Henriques GEP, et al. Influence of chemical and mechanical polishing on water sorption and solubility of denture base acrylic resins. Braz Dent J. 2004;15(3):225–30. [Google Scholar] [Crossref]

- Kedjarune U, Charoenworaluk N, Koontongkaew S. Release of methyl methacrylate from heat-cured and autopolymerized resins: cytotoxicitytesting related to residual monomer. Aust Dent J. 1999;44(1):25–30. [Google Scholar] [Crossref]

- KostiÄ? M, StanojeviÄ? J, TaÄiÄ? A, et al. Determination of residual monomer content in dental acrylic polymers and effect after tissues implantation. Biotechnol Biotechnol Equip. 2020;34(1):254–63. [Google Scholar] [Crossref]

- Ouellette RJ, Rawn JD. Organic chemistry study guide: Key Concepts, Problems, and Solutions. Elsevier; 2014;588. [Google Scholar]