Effect of drying temperature on beef lung powder's nutritive, practical, pasting, and storage durability as a potential protein source for dietary supplements

Received: 20-Jul-2022, Manuscript No. PULJFDR-22-5698; Editor assigned: 22-Jul-2022, Pre QC No. puljfdr-22-5698 (PQ); Accepted Date: Aug 05, 2022; Reviewed: 30-Jul-2022 QC No. PULJFDR-22-5698 (Q); Revised: 03-Aug-2022, Manuscript No. PULJFDR-22-5698 (R); Published: 08-Aug-2022, DOI: :10.37532/puljfdr.22.6(4).1-2

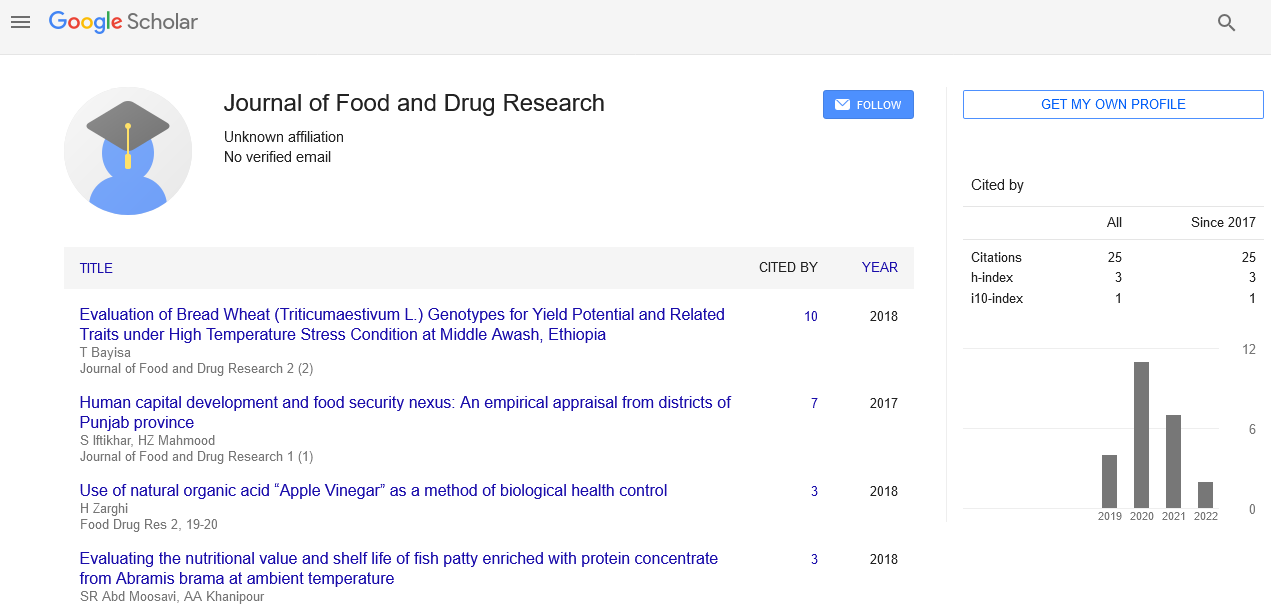

Citation: Miller M. Effect of drying temperature on beef lung powder's nutritive, practical, pasting, and storage durability as a potential protein source for dietary supplements. J. Food Drug Res. 2022; 6(4),1-2

This open-access article is distributed under the terms of the Creative Commons Attribution Non-Commercial License (CC BY-NC) (http://creativecommons.org/licenses/by-nc/4.0/), which permits reuse, distribution and reproduction of the article, provided that the original work is properly cited and the reuse is restricted to noncommercial purposes. For commercial reuse, contact reprints@pulsus.com

Abstract

In the current study, a protein compound for inexpensive human food supplements was created using beef lungs. To create a powder-based intermediate product, beef lungs were dried at 50,°C 70°C, and 100 ° C in an air dryer before being pulverised. All samples of beef-lung powder (BLP) dried at various temperatures displayed a 300% waterbinding capacity. The haem-iron concentration and protein quality were considerably reduced by drying temperature, with samples dried at 50°C having the highest haem-iron level (41% of total-iron content). With rising drying temperatures, a discernible rise in glycine content was seen. The BLP-samples dried at 50°C demonstrated the lowest protein degradation according to SDS-PAGE data. All drying temperatures yielded microbiologically safe products, but BLPsamples dried at 50°C had the maximum protein- and lipid-oxidative stability. After six months of storage, the average values of all the microbial counts were within acceptable ranges. The viscosity of the semolina dough reduced (P 0.05) when 10% BLP dried at 70 and 100 °C was added. The addition of 10% BLP dried at 50°C had no influence on the apparent viscosity. The product produced by drying beef lungs at 50°C was of high grade. The outcomes showed that BLP has the potential to be a prospective and economical The nutritional status of numerous social groups, including the undernourished, the elderly, pregnant women, and those recovering from surgery, is significantly improved by protein supplements.

Key Words

Protein compound; Beef lungs; Pulverized; Haem-iron concentration

Introduction

The cost of protein supplements has increased across the board due to expensive protein sources and strong demand. In order to produce protein products that are both economical and of excellent quality, scientists and the food industry have begun examining underutilised protein sources. There is abundant chance to use these co-products as a source of protein products because the carcase only makes up 45–60% of an animal's live weight and the majority of the remaining weight is made up of protein-rich co-products (lungs, kidney, heart, and tongue) (such as protein concentrates and protein hydrolysates). Since co-products have a long history of being consumed safely by many people worldwide, turning underutilised coproducts into wholesome and secure protein supplements is a smart move. Utilizing co-products will increase industry profit margins while lowering the environmental effect of material disposal. The use of co-products, such as beef lungs, will help boost production efficiency because the beef business has a high cost of production. In many civilizations, beef lungs have been consumed as food due to their high protein content, which is 87% on a dry weight basis However, it lacks aesthetic appeal and frequently encounters regulatory challenges when used as human food .Because of this, beef lungs are typically converted and become low-value materials or are infrequently utilised to make pet food.

Lungs in particular are particularly vulnerable to microbial deterioration and contamination. Drying is one of the simplest techniques to increase the storage stability of co-products, and dried powders made from various protein sources have been developed successfully. In a prior study, we showed that beef lung protein powder (BLP) had exceptional nutritional qualities, demonstrating its potential as a component in the creation of affordable protein-based food supplements. Such a product could be extremely important in helping individuals in underdeveloped and low-income nations— especially children and the elderly—meet their protein needs. In the current investigation, BLP powder was produced using the hot airdrying method. While there are other alternative drying techniques that can be employed alone or in combination to dry beef lungs, ncluding freeze drying, infrared drying, fluidized bed drying, dielectric drying, refractance window, and touch drying. However, the hot air-drying process is far more appropriate for commercial production of cost-effective BLP powder since it has reduced startup costs, low operational costs, and is extensively used in low-income nations. Considering that it is a good source of animal proteins and highly bioavailable iron, it is necessary to optimise the drying process and other processing steps in order to keep these priceless nutrients in the finished product. Before suggesting BLP powder as an element in the creation of protein supplements, it is imperative to characterise it thoroughly and assess its storage stability.