Effective management and control of the cold chain by application of Time Temperature Indicators (TTIs) in food packaging

Received: 31-Jan-2018 Accepted Date: Feb 16, 2018; Published: 22-Feb-2018

Citation: Stergiou F. Effective management and control of the cold chain by application of Time Temperature Indicators (TTIs) in food packaging. J Food Clin Nutr 2018;1(1):12-15.

This open-access article is distributed under the terms of the Creative Commons Attribution Non-Commercial License (CC BY-NC) (http://creativecommons.org/licenses/by-nc/4.0/), which permits reuse, distribution and reproduction of the article, provided that the original work is properly cited and the reuse is restricted to noncommercial purposes. For commercial reuse, contact reprints@pulsus.com

Abstract

Different temperature conditions can cause food loss and waste and the United Nations are pushing towards the reduction of food waste. One of the greatest problems in the food trade is the effective management of the cold chain, as short-living foodstuffs have to be maintained below 5°C. If the temperature levels are not below 5°C along cold chains food can be spoiled and this in turn can lead to food poisoning. Better temperature control along cold chain can make food safer, but the most effective management of the cold chain can be achieved through establishing control systems, such as intelligent packaging. Such forms include Time Temperature Indicators (TTIs) and the most common type is biological, polymerised, diffusionbased, electrochemical and photochemical. TTIs can have a straightforward application in the industry as scientists developed a model to be massively produced.Keywords

TTIs, Cold chain, Food packaging, Food waste, Temperature controlsIntroduction

Different temperature conditions cause unreliable printed shelf lives [best before dates] and food waste [1]. As a result, in the EU, the percentage of food losses in food manufacturing is up to 39%, and a further 5% along the distribution chain [2]. The United Nations have agreed to work towards the achievement of a more sustainable world by 2030 and the reduction of food waste is one of the targets [3].

One of the most dominant aspects affecting the quality of chilled food is the storage temperature [4]. In short-living foodstuffs, such as dairy products, raw meat and fish, sellers should pay more attention towards the elimination of wrong storage temperature, as it is essential to maintain the cold chain below 5°C or at the temperature that is indicated on the products’ label as required by the producer [5].

Nowadays, refrigeration is one of the most widely practiced method of preserving fresh foods and the improper use of this process can increase the potential risk that microbial hazards will advance and this in turn can lead to food poisoning [4]. As a result, temperature controls along cold food supply chains are crucial for maintaining food quality and ensuring the safety of food products [1].

There are many different ways that cold chain can be effectively managed and controlled. One of them, the Time Temperature Indicators [TTIs] have the benefit of being low cost and can be easily integrated in packaging [6,7]. TTIs are easily measurable “smart labels”, which visually reflect the temperature history of the food products depending on time and temperature changes [7]. This is why they can be extensively used in food packaging [6]. As it becomes apparent, implementing a TTI-based mechanism in food packaging could lead to a better monitoring of the cold chain, development of stock rotation, reduction of food waste and ultimately effective shelf-life management [8].

Cold Chains and Storage

A successful cold chain depends on various factors, such as the storage room temperature, the kind of refrigerators and the food position within [9]. In the European Union, Regulation [EC] No 852/2004 has established the requirement to maintain the cold chain for food products that cannot be stored safely at ambient temperatures such as fresh fish and raw meat. In relation to the correct management of the cold chain maintenance, it is needed to control temperatures, and check the suitable and functioning refrigeration or freezing equipment [9]. However, if the temperature levels are not controlled along cold chains, the possible risk of microbial hazards will be increased and can lead to foodborne illness [4]. A variety of aspects, such as legislation, industry habits, product characteristics, supply chain system, global food trade and the relationship between food supply chains participates, influence the management of cold food supply chain [4]. The most critical part of food supply chain participants is Quality Control, as they are required to assure storage and handling temperatures. For example, they are required to take temperature samples of received foods and monitor their cooling units [1]. Exposure to high temperature decreases the shelf life of the product, which is normally tagged on the food package, and it is hard to estimate whether the products are still safe for the consumers after being exposed to high or not recommended temperatures [10]. In addition, wrong measuring of the surrounding temperature instead of the temperature close to the actual products can cause the false rejection or acceptance of entire food batches, based on temperatures affecting only a part of the batch [11]. Raab, et al. has found that temperature mappings within a poultry supply chain showed temperature fluctuations between -5°C and 15°C within a vehicle at different locations during unloading, while the actual product temperature had only changed slightly. More specifically during the summer, where the outside temperature is high, delivery procedures have been reported to result in broken cold chains [12]. Therefore, it is important to note that the lack of accurate temperature records for food products, which reveal whether the cold chain has been maintained or not, can lead to unnecessary food waste since food cold chain participants do not want to risk consumers’ health [1].

On the other hand, cold chain does not end at the stores, because when consumers buy food, they have to maintain the cold chain from the store till their house. Actually, it has been shown that consumers contribute the most towards food waste in the European Union with an average 167 kg waste per capita per year [13]. This is why the improvement of storage conditions in households and the refrigeration appliances therein can have a positive impact to the shelf life of fresh products, as the nominal refrigerator temperature of 4°C is suboptimal for a considerable number of food products. It has been found that even a small saving of no more than 2% on food purchases can potentially save energy and reduce household monetary expenses [13].

Intelligent Packaging

Intelligent packaging can give a solution for maintaining the cold chain and it can be the main action point to control food waste [14]. Yam, et al. defined intelligent packaging as “a packaging system that is capable of carrying out intelligent functions [such as detecting, sensing, recording, tracing, communicating, and applying scientific logic] to facilitate decision making to extend shelf life, enhance safety, improve quality, provide information, and warn about possible problems” [15].

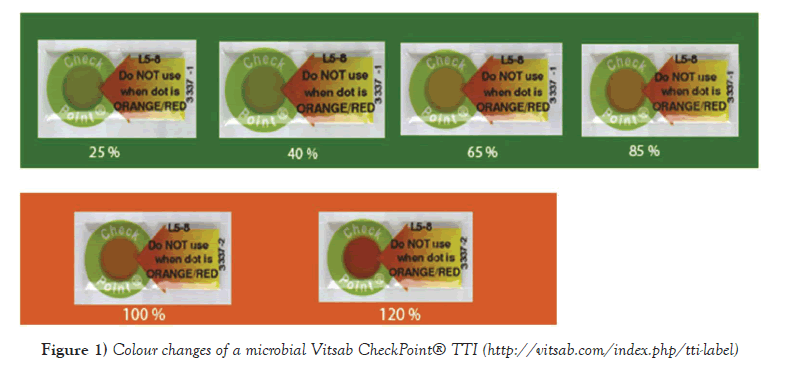

There are different types of intelligent packaging which can contribute to the management and control of the cold chain. The most common ones are biological [enzymatic and microbial] [16,17], polymerized, diffusionbased [18], electrochemical and photochemical [19]. For example, a Vitsab Checkpoint® TTI label is based on the controlled enzymatic hydrolysis of a lipid substrate, which results in a colour change. The TTI can be activated by a pressing on the “window” to break the seal between the enzyme and substrate mini pouches [20]. When the enzyme and substrate have been mixed, a homogenous green colour appears in the “window”, as it can be seen in the Figure 1. This serves as evidence for excellent shipping and storage conditions for the packaged goods. In the event that the colour in the window is not green, but yellow to light orange, then it can be assumed that the product has been compromised by time or temperature exposure and it is thus no longer acceptable [20].

Figure 1: Colour changes of a microbial Vitsab CheckPoint® TTI (http://vitsab.com/index.php/tti-label)

Scientists from Zhejiang University and Food and Drug Administration of China developed a biological [enzymatic] TTI that is based on the reaction between urease and carbamide [21]. Urease is a nickel-dependent enzyme, which can hydrolyse carbamide to carbamic acids and ammonia and can be found in plants, bacteria and vegetables, but not in animals [22]. After the hydrolysis if there is a pH indicator in the solution, such as phenol red, then the pH value of the carbamide solution will increase and the solution colour will change from yellow to red [21]. This enzymatic TTI showed great performance as the results are remarkable regarding the pH indication and the TTI colour change. In other words, the relationship of the colour change of the TTI under different temperatures evidenced that this product would be applied to temperature depended foods, but there is a need for further research to adjust the relative amount of urease and carbamide.

Scientists from Woosong University and Dongguk University-Seoul from the Republic of Korea developed another enzyme-based TTI using the Laccase enzyme. Their results showed that by controlling the concentration of Laccase, it is achievable to adjust the indicator’s colour conversion time and this enabling assessment of the quality of different products having different shelf lives. Most of Enzymatic TTI use synthetic chromogenic substrates, which are expensive and they have to be hydrolysed in order to produce colour [17]. Laccases belong to the Amin oxidase [copper-containing] family of enzymes, which are commonly used in several industrial processes including paper producing, prevention of wine discoloration, detoxification of environmental pollutants, oxidation of dyes, and production of chemicals from lignin [23]. Even though enzymatic TTI are expensive to be produced, they have numerous advantages, including higher visibility and also a lower procedure cost when the TTI is based on an enzyme, such as Laccase, that uses natural pigments as its substrate [17]. More specifically, through the application of Laccase as a TTI there will be advantages, such as the ability to develop a TTI with a wide range of activation energy, the catalytic mechanism of Laccase examined so far seems to be simple in producing and lastly laccase is safer for the consumer and sustainable [17].

This kind of TTI is microbial and indicates the bacterial growth and metabolism that take place in the TTI system itself and replies straight to the microbial food spoilage [24]. As a result, microbial TTIs seem to be much more accurate in controlling the quality loss of food products, which is spoiled by microorganism than other TTI [25]. TTI microorganism carries out the perception function of time/temperature by changing the growth and metabolic activity rate according to room temperature, which is the core element of a microbial TTI, and influences the pH indicator as well as the choice of substrate media [25]. Moreover, one of the most important conditions for a successful TTI is the selection of an appropriate TTI microorganism for the microbial growth [25]. It is worth mentioning that the degradation of the quality of the majority of chilled food products which are high in protein, is the result of the growth and metabolism activities of the specific spoilage organism [SSO]. When fresh products reach at the stage of not being sensory acceptable, then the SSO has reached a specific population level, the otherwise called “spoilage level” [26]. Kim, et al. provided interesting insights in relation to the methodologies of selecting a pH indicator in order to succeed in having an accurate indication effect [18]. Firstly, lactic acid metabolism and microbial growth in a microbial TTI cause a various pH range and should be determined. After that, potential single or mixed pH-indicators with similar pH change ranges have to be selected and the best pH indicator, single or mixed, which satisfies the abovementioned standards, is applied.

A very interesting project of a prototype isopropyl palmitate [IPP], a diffusionbased TTI system, for controlling the microbial growth of non-pasteurized angelica [NPA] juice based on temperature abuse has been conducted by scientists from the Yonsei University, King Saud University, Culture University and 3M Korea. The study mentioned above aimed to come up with a model that would be able to predict the response of a diffusionbased TTI structure and to assess if the TTI system could be successfully applied as an indicator of the initiation of possible microbial growth in NPA juice or related types of fresh food products because of temperature abuse while in storage and transportation [18]. In this project, it was developed a kinetic model and showed high prediction of food spoilage under isothermal storing conditions. On the one hand, when the storage temperature is at 25°C, microbial growth shows an obvious rise. On the other hand, at 5°C, microbial growth does not increase. As a result, it can be argued that refrigerated storage conditions can reduce microbial growth in foods [18,27]. The above mentioned TTI worked well on temperature changes, but it was only verified for indication of temperature abuse of more than 13.5°C [18]. This means that this kind of diffusion-based TTI can be helpful for controlling temperature abuse and microbial quality during storage and transportation of only single packages of food products, which do not seem to get spoiled under 13.5°C.

Wan and Knoll used a different device based on an electrochemical pseudotransistor in structured conductive polymers [10]. This TTI had all the basic functions, such as clock, temperature sensor, and electrical switch, but this was an important and innovate study, because it was the first time that this pseudo-transistor-TTI was combined with a radio frequency identification [RFID] technique. A TTI–RFID label can used for better protection of shortliving foods by using TTI and RFID readers, because it can work as an “overtemperature alarm” system, to indicate when a temperature abuse has been occurred [28]. This type of TTI can be used as a new alternative procedure to control the safety of perishable foods. It was also found that structured conductive polymers can be used as a powerful TTI with an electrical switch and it can be concluded that the migration length in TTI based on an electrochemical pseudo-transistor in structured conductive polymers can be used as a smart and powerful TTI in the studies and market [10].

One of the newest photochemical TTI is The OnVuTM [Ciba Specialty Chemicals & Freshpoint, SW], which introduced the solid state reaction. This TTI can be activated by UV light, as they have photosensitive compounds, organic pigments, such as benzyl pyridines, which can change colour with time at rates determined by temperature. As we can see in Figure 2, the blue inner heart [indicator] changes to white as a result of time and temperature. This system can be used as a label or printed directly onto the food package [29]. In addition, this TTI can be applied as a photosensitive ink [30].

TTIs and Mass Production

A very useful for the industry new manufacturing procedure was developed by Zabala, et al. [6]. They proposed a roll-to roll printing technology that allows a functional ink to be limited to certain areas of a porous paper while maintaining the moisture content within. These TTIs can have a straightforward application to the industry due to the use of traditional printing technologies, such as screen printing, whose main features are repeatability, reproducibility and low cost manufacturing [6]. The printing process proposed in this project can be used to produce a TTI of a wide options of structure, amount and colour changes with time and temperature. This microbial smart labels have been successfully produced using this production process and can be easily applied in food packaging, as they can be a great mechanism for cold chain management [6].

Conclusion

As it can be concluded from the discussion above, during transportation food products are not maintained in a standard temperature and this can cause spoilage of the transported food. The cold chain participants play a key for consumers’ health, as they can maintain and control food’s microbial load in low levels by taking simple temperature measurements through the cold chain and by keeping accurate temperature records [1].

Active and intelligent packaging decreases the number of retailer and consumer complaints and appears to offer satisfactory solutions in enhancing food safety. There are still a number of critical aspects, such as economics, legislation (e.g. migration of components from packaging materials and labelling) and consumers preferences, which need to be taken into account and further research to be conducted for the successful application of the intelligent packaging solutions in the industry [20].

Intelligent packages with applied TTI keep track of the temperature throughout the cold chain and seem to be the future of packaging. The easy use of TTI can cause less food waste while protecting consumer health more efficiently.

REFERENCES

- Göransson M, Nilsson F, Jevinger A. Temperature Performance and Food Shelf-Life Accuracy in Cold Food Supply Chains – Insights from Multiple Field Studies. Food Control 2017.

- Monier V, Mudgal S, Escalon V, et al. Preparatory Study on Food Waste across EU 27. European Commission (DG ENV) Directorate C-Industry, 2010.

- Sustainable development.Un.Org. Transforming Our World: The 2030 Agenda For Sustainable Development. Sustainable Development Knowledge Platform, 2017.

- Jol S, Kassianenko A, Wszol K, et al. The Cold Chain, One Link in Canada’s Food Safety Initiatives. Food Control 2007;18:713-715.

- Yam K, Takhistov P, Miltz J. Intelligent Packaging: Concepts and Applications. J Food Sci 2005;70:R1-R10.

- Zabala S, Castán J, Martínez C. Development of a Time–Temperature Indicator (TTI) Label by Rotary Printing Technologies. Food Control 2015;50:57-64.

- Taoukis PS (2010) 14 - Commercialization of Time-Temperature Integrators for Foods. In Doona CJ, Kustin K, Feeherry FE (Eds), Case Studies In Novel Food Processing Technologies. Woodhead Publishing, pp.351-366.

- Pavelková A. Time Temperature Indicators as Devices Intelligent Packaging. Acta Universitatis Agriculturae Et Silviculturae Mendelianae Brunensis 2013;61:245-251.

- Bernardino BZ, Maria NJ, M Teresa VC, et al. Effectiveness of the Cold Chain Control Procedure in the Retail Sector in Southern Spain. Food Control 2016;59:614-618.

- Wan X, Knoll M. A New Type of TTI Based On an Electrochemical Pseudo Transistor. J Food Eng 2016;168:79-83.

- Raab V, Bruckner S, Beierle E, et al. Generic Model for the Prediction of Remaining Shelf Life In Support Of Cold Chain Management in Pork and Poultry Supply Chains. Journal on Chain and Network Science 2008;8:59-73.

- Carullo A, Corbellini S, Parvis M, et al. A Wireless Sensor Network for Cold-Chain Monitoring. IEEE Transactions on Instrumentation and Measurement 2009;58:1405-1411.

- Holsteijn F, Kemna, R. Minimizing Food Waste by Improving Storage Conditions in Household Refrigeration. Resources, Conservation and Recycling 2017;128:25-31.

- Mohebi E, Marquez L. Intelligent Packaging in Meat Industry: An Overview of Existing Solutions. J Food Sci Technol 2014;52:3947-3964.

- Monier V, Mudgal S, Escalon V, et al. 'Preparatory Study on Food Waste across EU 27', European Commission (DG ENV) Directorate C-Industry, 2010.

- Ellouze M, Augustin J. Applicability of Biological Time Temperature Integrators as Quality and Safety Indicators for Meat Products. Int J Food Microbiol 2010;138:119-129.

- Kim K, Kim E, Lee S. New Enzymatic Time–Temperature Integrator (TTI) That Uses Laccase. J Food Eng 2012;113:118-123.

- Kim J, Ghafoor K, Ahn J, et al. Kinetic Modeling and Characterization of a Diffusion-Based Time-Temperature Indicator (TTI) For Monitoring Microbial Quality of Non-Pasteurized Angelica Juice. LWT - Food Sci Technol 2016;67:143-150.

- Tsironi T, Stamatiou A, Giannoglou M, et al. Predictive Modelling And Selection Of Time Temperature Integrators For Monitoring The Shelf Life Of Modified Atmosphere Packed Gilthead Seabream Fillets. LWT - Food Sci Technol 2011;44:1156-1163.

- Fang Z, Zhao Y, Warner R, et al. Active and Intelligent Packaging in Meat Industry. Trends Food Sci Technol 2017;61:60-71.

- Wu D, Wang Y, Chen J, et al. Preliminary Study on Time– Temperature Indicator (TTI) System Based On Urease. Food Control 2013;34:230-234.

- Alizadeh H, Kandula D, Hampton J, et al. Urease Producing Microorganisms under Dairy Pasture Management in Soils across New Zealand. Geoderma Regional 2017;11:78-85.

- Rodríguez Couto S, Toca Herrera JL. Industrial and Biotechnological Applications of Laccases: A Review. Biotechnol Adv 2006;24:500-513.

- Vaikousi H, Biliaderis C, Koutsoumanis K. Applicability of a Microbial Time Temperature Indicator (TTI) For Monitoring Spoilage Of Modified Atmosphere Packed Minced Meat. Int J Food Microbiol 2009;133:272-278.

- Zhang X, Sun G, Xiao X, et al. Application of Microbial Ttis as Smart Label for Food Quality: Response Mechanism, Application and Research Trends. Trends Food Sci Technol 2016;51:12-23.

- Vaikousi H, Biliaderis C, Koutsoumanis K. Development of a Microbial Time/Temperature Indicator Prototype for Monitoring the Microbiological Quality of Chilled Foods. Appl Environ Microbiol 2008;74:3242-3250.

- Lu L, Zheng W, Lv Z, et al. Development and Application of Time-Temperature Indicators Used on Food during the Cold Chain Logistics. Packaging Technology and Science 2012;26:80-90.

- Herbon A, Levner E, Cheng T. Perishable Inventory Management With Dynamic Pricing Using Time–Temperature Indicators Linked To Automatic Detecting Devices. Int J Prod Econ 2014;147:605-613.

- Koutsoumanis K, Gougouli M. Use of Time Temperature Integrators in Food Safety Management. Trends Food Sci Technol 2015;43:236-244.

- Vieira M. Developments in Active and Intelligent Food Packaging. J Food Process Technol 2016;07:07.