Heat Exchanger Technology and Applications: Groundsource Heat Pump System for Buildings Heating and Cooling

Received: 08-Sep-2022, Manuscript No. PULJECT-22-5402; Editor assigned: 10-Sep-2022, Pre QC No. PULJECT-22-5402(PQ); Accepted Date: Nov 22, 2022; Reviewed: 12-Sep-2022 QC No. PULJECT-22-5402(Q); Revised: 20-Sep-2022, Manuscript No. PULJECT-22-5402(R); Published: 29-Nov-2022, DOI: 10.37532/Pulject.2022 .6(5); 01-08

This open-access article is distributed under the terms of the Creative Commons Attribution Non-Commercial License (CC BY-NC) (http://creativecommons.org/licenses/by-nc/4.0/), which permits reuse, distribution and reproduction of the article, provided that the original work is properly cited and the reuse is restricted to noncommercial purposes. For commercial reuse, contact reprints@pulsus.com

Abstract

Geothermal Heat Pumps (GSHPs), or Direct Expansion (DX) ground source heat pumps, are a highly efficient renewable energy technology, which uses the earth, groundwater or surface water as a heat source when operating in heating mode or as a heat sink when operating in a cooling mode. It is receiving increasing interest because of its potential to reduce primary energy consumption and thus reduce emissions of the greenhouse gases (GHGs). The main concept of this technology is that it utilises the lower temperature of the ground (approximately<32°C), which remains relatively stable throughout the year, to provide space heating, cooling and domestic hot water inside the building area. The main goal of this study is to stimulate the uptake of the GSHPs. Recent attempts to stimulate alternative energy sources for heating and cooling of buildings has emphasised the utilisation of the ambient energy from ground source and other renewable energy sources. The purpose of this study, however, is to examine the means of reduction of energy consumption in buildings, identify GSHPs as an environmental friendly technology able to provide efficient utilisation of energy in the buildings sector, promote using GSHPs applications as an optimum means of heating and cooling, and to present typical applications and recent advances of the DX GSHPs. The study highlighted the potential energy saving that could be achieved through the use of ground energy sources. It also focuses on the optimisation and improvement of the operation conditions of the heat cycle and performance of the DX GSHP. It is concluded that the direct expansion of the GSHP, combined with the ground heat exchanger in foundation piles and the seasonal thermal energy storage from solar thermal collectors, is extendable to more comprehensive applications.

Keywords

Geothermal heat pumps; Direct expansion; Ground heat exchanger; Heating and cooling

Introduction

he earth’s surface acts as a huge solar collector, absorbing radiation from the sun. In the UK, the ground maintains a constant temperature of 11°C-13°C several meters below the surface all the year around [1]. Among many other alternative energy resources and new potential technologies, the Ground Source Heat Pumps (GSHPs) are receiving increasing interest because of their potential to reduce primary energy consumption and thus reduce emissions of greenhouse gases [2].

Direct expansion GSHPs are well suited to space heating and cooling and can produce significant reductions in carbon emissions. In the vast majority of systems, space cooling has not been normally considered, and this leaves ground-source heat pumps with some economic constraints, as they are not fully utilised throughout the year. The tools that are currently available for the design of a GSHP system require the use of key site-specific parameters such as temperature gradient and the thermal and geotechnical properties of the local area. The main core with several channels will be able to handle heating and cooling simultaneously, provided that the channels to some extent are thermally insulated and can be operated independently as single units, but at the same time function as integral parts of the entire core. Loading of the core is done by diverting warm and cold air from the heat pump through the core during periods of excess capacity compared to the current needs of the building [3, 4]. The cold section of the core can also be loaded directly with air during the night, especially in spring and fall when nighttimes are cooler and daytimes are warmer. The shapes and numbers of the internal channels and the optimum configuration will depend on the operating characteristics of each installation. The efficiency of a GSHP system is generally much greater than that of conventional air-source heat pump systems. Higher COP (Coefficient of Performance) is achieved by a GSHP because the source/sink earth temperature is relatively constant compared to air temperatures. Additionally, heat is absorbed and rejected through water, which is a more desirable heat transfer medium due to its relatively high heat capacity.

The GSHPs in some homes also provide

• Radiant floor heating.

• Heating tubes in roads or footbaths to melt snow in the winter.

• Hot water for outside hot tubs.

• Energy to heat hot water

With the improvement of people’s living standards and the development of economies, heat pumps have become widely used for air conditioning. The driver to this was that environmental problems associated with the use of refrigeration equipment, ozone layer depletion, and global warming are increasingly becoming the main concerns in developed and developing countries alike. With the development and enlargement of cities in cold regions, conventional heating methods can severely pollute the environment. In order to clean the cities, the governments drew many measures to restrict citizen heating by burning coal and oil and encouraging them to use electric or gas-burning heating. New approaches are being studied and a solar-assisted reversible absorption heat pump for small power applications using water, ammonia is under development [5].

An air-source heat pump is convenient to use and so it is a better method for electric heating. The ambient temperature in winter is comparatively high in most regions, so heat pumps with high efficiency can satisfy their heating requirement. On the other hand, a conventional heat pump is unable to meet the heating requirement in severely cold regions anyway, because its heating capacity decreases rapidly when the ambient temperature is below-10°C. According to the weather data in cold regions, the air-source heat pump for heating applications must operate for long times with high efficiency and reliability when ambient temperature is as low as 15°C [6]. Hence, much research and development has been conducted to enable heat pumps to operate steadily with high efficiency and reliability in lowtemperature environments [7]. For example, the burner of a room air conditioner, which uses kerosene, was developed to improve the performance in low outside temperature. Similarly, the packaged heat pump with variable frequency scroll compressor was developed to realise high-temperature air supply and high capacity even under the low ambient temperature of–10°C to–20°C. Such heat pump systems can be conveniently used for heating in cold regions. However, the importance of targeting the low capacity range is clear if one has in mind that the air conditioning units below 10 kW cooling account for more than 90% of the total number of units installed in the EU [8].

Methods and laboratory measurements

This communication describes the details of the prototype GSHP test rig, and details of the construction and installation of the heat pump, heat exchanger, heat injection fan, and water supply system. It also presents a discussion of the experimental tests being carried out.

Main experimental test rig

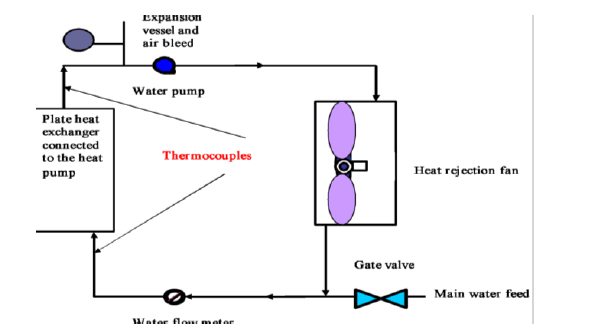

The schematic of the test rig that was used to support the two groundloop heat exchangers is shown in Figure 1. It consisted of two main loops: heat source loop and evaporation heat pump. Three boreholes were drilled each 30 m deep to provide sufficient energy. The closedloop systems were laid and installed in a vertical well. The groundloop heat exchangers were connected to the heat pump.

Direct expansion heat pump installation

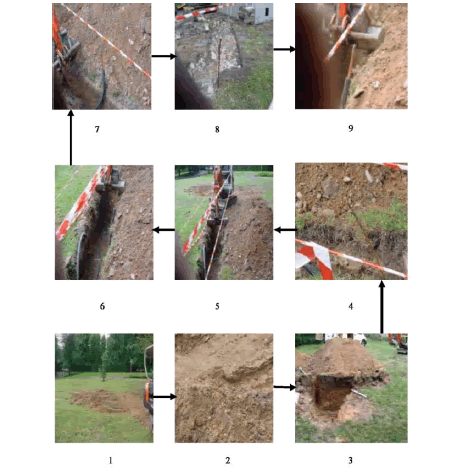

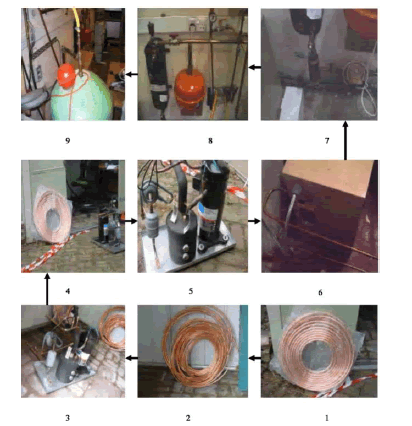

The experimental work undertaken was separated into three parts. The first part dealt with drilling three boreholes each 30 m deep, digging out the pit and connecting the manifolds, and preparation of coils. Holes were grouted with bentonite and sand. The pipes were laid and tested with nitrogen. Then, the pit was backfilled and the heat pump was installed. The second part was concerned with the setting up of the main experimental rig: construction and installation of the heat injection fan, water pump, expansion valve, flow meter, electricity supply, heat exchanger, and heat pump. The third part was the installation of the refrigerator and measurements.

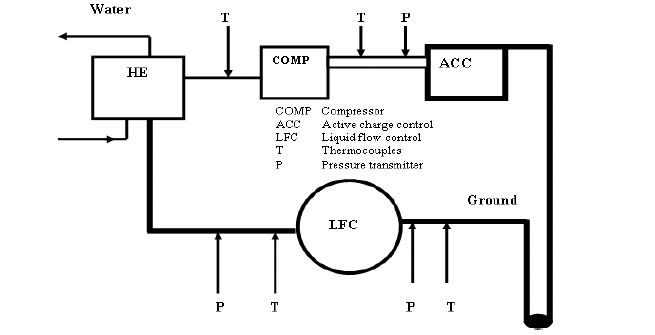

The aim of this project is to present and develop a GSHP system to provide heating and cooling for buildings (Figure 2). The heat source loop consisted of two earth loops: one for vapour and one for liquid. A refrigeration application is only concerned with the lowtemperature effect produced at the evaporator; while a heat pump is also concerned with the heating effect produced at the condenser.

The Earth-Energy Systems, EESs, have two parts; a circuit of underground piping outside the house, and a heat pump unit inside the house. And unlike the air-source heat pump, where one heat exchanger (and frequently the compressor) is located outside, the entire GSHP unit for the EES is located inside the house.

The outdoor piping system can be either an open system or a closed loop. An open system takes advantage of the heat retained in an underground body of water. The water is drawn up through a well directly to the heat exchanger, where its heat is extracted. The water is discharged either to an aboveground body of water, such as a stream or pond, or back to the underground water body through a separate well. Closed-loop systems, on the other hand, collect heat from the ground by means of a continuous loop of piping buried underground. An antifreeze solution (or refrigerant in the case of a DX earth-energy system), which has been chilled by the heat pump's refrigeration system to several degrees colder than the outside soil, and circulates through the piping, absorbing heat from the surrounding soil.

The Direct Expansion (DX) GSHP installed for this study was designed taking into account the local meteorological and geological conditions. The site was at the School of the Built Environment, the University of Nottingham, where the demonstration and performance monitoring efforts were undertaken (Figures 3, 4). The heat pump has been fitted and monitored for one year. The study involved the development of a design and simulation tool for modeling the performance of the cooling system, which acts a supplemental heat rejecting system using a closed-loop GSHP system. With the help of the Jackson Refrigeration (Refrigeration and Air Conditioning engineers) the following were carried out:

• Connection of the ground loops to the heat pump.

• Connection of the heat pump to the heat exchanger.

• Vacuum on the system.

• Charging the refrigeration loop with R407C refrigerant.

Water supply system

The water supply system consisted of a water pump, boiler, water tank, and expansion and valve flow meter (Figure 4). A thermostatically controlled water heater supplied warm water, which was circulated between the warm water supply tank and the warm water storage tank using a pump to keep the surface temperature of the trenches at the desired level.

The ground source heat pump system, which uses a ground source with a smaller annual temperature variation for heating and cooling systems, has increasingly attracted market attention due to lower expenses to mine for installing underground heat absorption pipes and lower costs of dedicated heat pumps, supported by environmentally oriented policies. The theme undertakes an evaluation of heat absorption properties in the soil and carries out a performance test for a DX heat pump and a simulated operation test for the system. These policies are necessary for identifying operational performance suitable for heating and cooling, to obtain technical data on the heat pump system for its dissemination and maintain the system in an effort of electrification. In these circumstances, the study estimated the heat properties of the soil in the city of Nottingham and measured thermal conductivity for the soil at some points in this city, aimed at identifying applicable areas for the ground source heat pump system.

Design and installation

Installation of the heat pump system and especially the ground heat exchanger needs to be carefully programmed so that it does not interfere with or delay any other construction activities. The time for installation depends on soil conditions, length of pipe, equipment required, and weather conditions. The DX systems are most suitable for smaller domestic applications.

The most important first step in the design of a GSHP installation is the accurate calculation of the building’s heat loss, its related energy consumption profile and the domestic hot water requirements. This will allow accurate sizing of the heat pump system. This is particularly important because the capital cost of a GSHP system is generally higher than for alternative conventional systems and economies of scale are more limited. Oversizing will significantly increase the installed cost for little operational saving and will mean that the period of operation under part load is increased. Frequent cycling reduces equipment life and operating efficiency. Conversely, if the system is undersized design conditions may not be met and the use of top-up heating, usually direct-acting electric heating, will reduce the overall system efficiency. In order to determine the length of heat exchanger needed to piping material. The piping material used affects life; maintenance costs, pumping energy, capital cost, and heat pump performance.

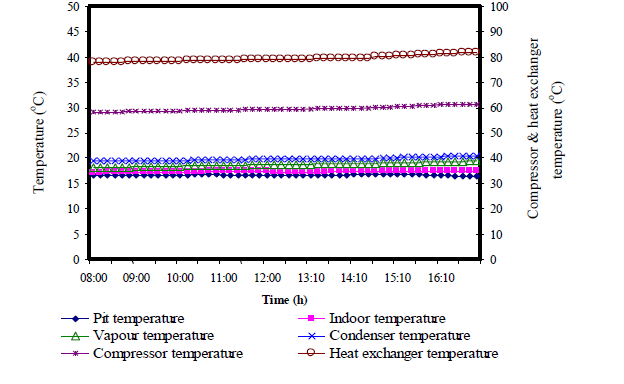

Heat pump performance

The need for alternative low-cost energy resources has given rise to the development of the DX-GSHPs for space cooling and heating. The performance of the heat pump depends on the performance of the ground loop and vice versa. It is therefore essential to design them together. Closed-loop GSHP systems will not normally require permissions/authorisations from the environment agencies. However, the agency can provide comments on proposed schemes to reduce the risk of groundwater pollution or derogation that might result. The main concerns are:

Given that there are limited empirical studies on heart valve surgeries, this review was based on the findings found on patients with cardiovascular diseases, heart failure, and Coronary Artery Bypass Graft (CABG).

• Risk of the underground pipes/boreholes creating undesirable hydraulic connections between different water-bearing strata.

• Undesirable temperature changes in the aquifer may result from the operation of a GSHP.

• Pollution of groundwater that might occur from leakage of additive chemicals used in the system.

Efficiencies for the GSHPs can be high because the ground maintains a relatively stable temperature allowing the heat pump to operate close to its optimal design point. Efficiencies are inherently higher than for air source heat pumps because the air temperature varies both throughout the day and seasonally such that air temperatures, and therefore efficiencies, are lowest at times of peak heating demand.

A heat pump is a device for removing heat from one place - the ‘source’ and transferring it at a higher temperature to another place. The heat pumps consist of a compressor, a pressure release valve, a circuit containing fluid (refrigerant), and a pump to drive the fluid around the circuit. When the fluid passes through the compressor it increases in temperature. This heat is then given off by the circuit while the pressure is maintained. When the fluid passes through the relief valve the rapid drop in pressure results in a cooling of the fluid. The fluid then absorbs heat from the surroundings before being recompressed. In the case of domestic heating, the pressurised circuit provides the heating within the dwelling. The depressurised component is external and, in the case of ground source heat pumps, is buried in the ground. Heat pump efficiencies improve as the temperature differential between ‘source’ and demand temperature decreases, and when the system can be ‘optimised’ for a particular situation. The relatively stable ground temperatures moderate the differential at times of peak heat demand and provide a good basis for optimisation.

The refrigerant circulated directly through the ground heat exchanger in a Direct Expansion (DX) system but most commonly GSHPs are indirect systems, where a water/antifreeze solution circulates through the ground loop and energy is transferred to or from the heat pump refrigerant circuit via a heat exchanger. This application will only consider closed-loop systems. The provision of cooling, however, will result in increased energy consumption and the efficiently it is supplied (Figure 5). The GSHPs are particularly suitable for new builds as the technology is most efficient when used to supply lowtemperature distribution systems such as underfloor heating. They can also be used for retrofit, especially in conjunction with measures to reduce heat demand. They can be particularly cost-effective in areas where main gas is not available or for developments where there is an advantage in simplifying the infrastructure provided.

Performance

The heat transfer between the GSHP and its surrounding soil is affected by a number of factors such as working fluid properties (e.g., 20% glycol) and its flow conditions, soil thermal properties, soil moisture content, and groundwater velocity and properties, etc. The GSHP has great potential to be one of the main energy sources in the future as it can be tapped in a number of different ways and can be used to produce hot water as well as electricity. It has a large spatial distribution with almost all countries having at least low enthalpy resources available (less than 125°C) and many countries around the world in both developing and developed countries are already harnessing it. It is a resource that has always been there and always with be and does not rely on specific factors such as the wind to be blowing or the sun to be shining, as is the case with other forms of renewable energies. The GSHP is inherently clean and environmentally sustainable and will soon become more economical than combustion (fossil fuel) plants as regulations on plant emission levels are tightened and expensive abatement measures such as carbon capture and storage become compulsory. This study urges the need for the GSHP to be considered much more strongly than it currently is in environmental policies as it has been overlooked as the main alternative to fossil fuels and other forms of renewable energies.

Geothermal power utilises the heat energy naturally produced within the earth. Its wide abundance and renewable nature make it an attractive alternative energy source to fossil fuels. The environmental impact of geothermal power plants is negligible in comparison to combustion plants and it is progressively becoming more financially viable as emission regulations are tightened. The technology is increasingly being utilised by countries all over the world, as there are many different ways in which geothermal can be harnessed. Geothermal power is very competitive with other sources of energy when it comes to energy costs. Table 2 shows the globally averaged energy costs in 2008 for different energy sources and shows what the potential future energy costs for different sources will be. As Figure 6 shows, geothermal is already generally more financially viable and cost-effective globally than other forms of renewable power, being on par with hydroelectricity (however, it is important to note that costs will vary between countries) [9].

Applications of geo exchanger system

Geoexchanger energy is a natural resource, which can be used in conjunction with heat pumps to provide energy for heating and hot water. CO2 emissions are much lower than gas-fired boilers or electric heating systems. Geothermal heating is more expensive to install initially, than electrical or gas-fired heating systems. However it is cheaper to run, has lower maintenance costs, and is cleaner in use than other sources of heating.

The temperature of the earth under 2 m of the surface is a fairly constant 10ºC throughout the year. At a depth of about 100 m, the temperature of any water or rock is at about 12°C throughout the year. The heat stored at this depth comes largely from the sun, the earth acting as a large solar collector. For very deep wells, in excess of about 170 m, there is an added component of heat from the core of the earth. As an approximation, one can add 3°C of heat gain for every 100 m of depth drilled into the earth.

A closed loop system takes the heat gained from the bedrock itself. In a vertical system a borehole of a diameter of about 150 mm is drilled, depth varies between 32 m and 180 m but will depend on the energy requirements. Multiple boreholes can be drilled. A pair of pipes with a special U-bend assembly at the bottom is inserted into the borehole and the void between pipe and hole is backfilled with a special grout solution so that the pipe is in close contact with the rock strata or earth. Fluid (referred to as ‘brine’ is then circulated through this loop and is heated up by the bedrock. Different rock types will give different results. In some cases, a number of boreholes will be made (for example, over a car park) to provide sufficient energy for the heat pump supply. If the ground is not suitable, horizontal loops can be laid or even trench-filled ‘slinky’ loops, which are very simple to install. However, trench-filled systems and horizontal systems require much more ground than vertical systems. If one has a pond or lake nearby then can lay a closed loop at the base of the pond (it needs to be about 2 m deep), or simply extract the water directly out of the lake at a low level and it elsewhere in the lake.

Heat pumps can be cheaper to operate than other heating systems because, by tapping into free heat in the outdoor air, ground or water supply, they give back more energy in the form of heat than the equivalent amount of electrical energy they consume. For example, in heating mode, a highly efficient heat pump could extract energy from the earth and transfer it into a building. For every 1 kWh of electrical energy used to drive the heat pump, around 3 kWh to 4 kWh of thermal energy will be produced. In cooling mode, the heat pump works in reverse, and heat can be extracted from a building and dissipated into the earth. Heat pumps that work in a heating mode are given a ‘coefficient of performance’ or ‘COP’ calculated by dividing the input kWh into the output kWh. This will give a COP figure, which varies with the input temperature and is the ratio of energy into energy out. In cooling mode, the ratio is called the ‘energy efficiency ratio’ or ‘EER’. When the EER and COP ratios are higher, the more efficient the unit is. Geothermal/GSHPs are self-contained systems. The heat pump unit is housed entirely within the building and connected to the outside-buried ground loop.

Conventional heating or cooling systems require energy from limited resources, e.g., electricity and natural gas, which have become increasingly more expensive and are at times subject to shortages. Much attention has been given to sources subject to sources of energy that exist as natural phenomena. Such energy includes geothermal energy, solar energy, tidal energy, and wind-generated energy. While all of these energy sources have advantages and disadvantages, geothermal energy, i.e., energy derived from the earth or ground, has been considered by many as the most reliable, readily available, and easily tapped off natural phenomena.

This study has dealt with the modelling of vertical closed-loop and ground source heat pump systems. The challenges associated with the design of these systems originate from the fact that they present a unique type of heat transfer problem. First, there are inherent inabilities to make direct observations in the subsurface environment with respect to both space and time. Second, heat transfer within the subsurface environment can be highly transient. Consequently, a considerable amount of research in the past decade has been geared towards optimising the design and performance of GSHP systems and this study is part of those efforts

The installation and operation of a geothermal system may be affected by various factors. These factors include but are not limited to, the field size, the hydrology of the site the thermal conductivity and thermal diffusivity of the rock formation, the number of wells, the distribution pattern of the wells, the drilled depth of each well, and the building load profiles. The performance of the heat pump system could also be improved by eliminating unnecessary running of the integral distribution pump. This would improve both the economic and the environmental performance of the system. The results of the soil properties investigation have also demonstrated that the moisture content of the soil has a significant effect on its thermal properties. When water replaces the air between particles it reduces the contact resistance. Consequently, the thermal conductivity varied from 0.25 W/m/K for dry soil to 2.5 W/m/K for wet soil. However, the thermal conductivity was relatively constant above a specific moisture threshold. In fact, where the water table is high and cooling loads are moderate, the moisture content is unlikely to drop below the critical level. In Nottingham, where the present study was conducted, soils are likely to be damp for much of the time. Hence, thermal instability is unlikely to be a problem. Nevertheless, when heat is extracted, there will be a migration of moisture by diffusion towards the heat exchanger and hence the thermal conductivity will increase.

Coefficient of performance

The heat transfer between the GSHP and its surrounding soil is affected by a number of factors such as working fluid properties (e.g., 20% glycol) and its flow conditions, soil thermal properties, soil moisture content, and groundwater velocity and properties, etc. The GSHP has great potential to be one of the main energy sources in the future as it can be tapped in a number of different ways and can be used to produce hot water as well as electricity. It has a large spatial distribution with almost all countries having at least low enthalpy resources available (less than 125°C) and many countries around the world in both developing and developed countries are already harnessing it. It is a resource that has always been there and does not rely on specific factors such as the wind to be blowing or the sun to be shining, as is the case with other forms of renewable energies. The GSHP is inherently clean and environmentally sustainable and will soon become more economical than combustion (fossil fuel) plants as regulations on plant emission levels are tightened and expensive abatement measures such as carbon capture and storage become compulsory. This study urges the need for the GSHP to be considered much more strongly than it currently is in environmental policies as it has been overlooked as the main alternative to fossil fuels and other forms of renewable energies.

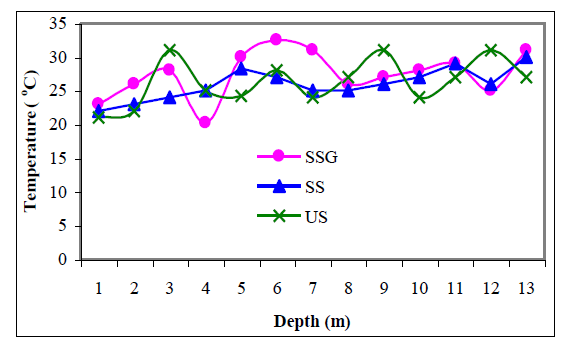

Geothermal power utilises the heat energy naturally produced within the earth. Its wide abundance and renewable nature make it an attractive alternative energy source to fossil fuels. The environmental impact of geothermal power plants is negligible in comparison to combustion plants and it is progressively becoming more financially viable as emission regulations are tightened. Technology is increasingly being utilised by countries all over the world, as there are many different ways in which geothermal energy can be harnessed. Geothermal power is very competitive with other sources of energy when it comes to energy costs. Geothermal is already generally more financially viable and cost-effective globally than other forms of renewable power, being on par with hydroelectricity (however, it is important to note that costs will vary between countries) [10, 11]. The experiments and calculations are conducted for Unsaturated Soil without groundwater flow (US), Saturated Soil without groundwater flow (SS) and Saturated Soil with Groundwater Flow (SSG) under the same conditions and their results are compared with each other in Figure 6.

Results and Discussion

The GSHPs are generally more expensive to develop, however, they have very low operating costs, therefore, it is necessary to have an idea of the energy use and demand of these equipments. The performances are normally rated at a single fluid temperature (0°C) for heating COP and a second for cooling EER (25°C). These ratings reflect temperatures for an assumed location and ground heat exchanger type and are not ideal indicators of energy use. This problem is compounded by the nature of ratings for conventional equipment. The complexity and many assumptions used in the procedures to calculate the seasonal efficiency for air-conditioners, furnaces, and heat pumps (SEER, AFUE, and HSPF) make it difficult to compare energy use with equipment rated under different standards. The accuracy of the results is highly uncertain, even when corrected for regional weather patterns. These values are not indicators of demand since they are seasonal averages and performance at severe conditions is not heavily weighted. The American Society of Heating, Refrigerating, and Air-Conditioning Engineers (ASHRAE) [12] recommends a weather-driven energy calculation, like the bin method, in preference to single measure methods like Seasonal Energy Efficiency Ratio (SEER), Seasonal Performance Factor (SPF), Energy Efficiency Rating (EER), Coefficient Of Performance (COP) Annual Fuel Utilisation Efficiency Rating (AFUE), and Heating Season Performance Factor (HSPF).

The GSHPs provide an effective and clean way of heating buildings worldwide. They make use of renewable energy stored in the ground, providing one of the most energy-efficient ways of heating buildings. They are suitable for a wide variety of building types and are particularly appropriate for low-environmental impact projects. They do not require hot rocks (geothermal energy) and can be installed in most of the world, using a borehole or shallow trenches or, less commonly, by extracting heat from a pond or lake. Heat collecting pipes in a closed loop, containing water (with a little antifreeze) are used to extract this stored energy, which can then be used to provide space heating and domestic hot water. In some applications, the pump can be reversed in summer to provide an element of cooling. The only energy used by the GSHP systems is electricity to power the pumps. Typically, a GSHP will deliver three or four times as much thermal energy (heat) as is used in electrical energy to drive the system. For a particularly environmental solution, green electricity can be purchased. The GSHP systems have been widely used in other parts of the world, including North America and Europe, for many years. Typically they cost more to install than conventional systems; however, they have very low maintenance costs and can be expected to provide reliable and environmentally friendly heating for more than 20 years. Ground source heat pumps work best with heating systems, which are optimised to run at a lower water temperature than is commonly used in the UK boiler and radiator systems. As such, they make an ideal partner for underfloor heating systems. The flow rate in the ground coil is 0.23 l/s. The heat collection rate varies from approximately 19 W to 27 W per meter length of collector coil. In winter, the ground coil typically operates with a temperature differential of about 5°C (i.e., a flow temperature from the ground of 2°C to 3°C and a return temperature to the ground coil of -1°C to -2°C). Icing up the return pipework immediately below the heat pump can be quite severe. The ground coil temperatures are considerably higher in summer when, for water heating, the temperature differential is similar but flow and return temperatures are typically 11°C and 6°C respectively. When the heat pump starts, the flow and return temperatures stabilise very quickly. Even over sustained periods of continuous operation, the temperatures remained stable. The ground coil appears adequately sized and could possibly be oversized. A residential GSHP system is more expensive to install than a conventional heating system. It is most cost-effective when operated year-round for both heating and cooling. In such cases, the incremental payback period can be as short as 3 years–5 years. A GSHP for a new residence will cost around 9%-12% of the home construction costs. A typical forced air furnace with flex ducting system will cost 5%-6% of the home construction costs. As stated in an alternative form, the complete cost of a residential GSHP system is $3,500-$5,500 per ton. Horizontal loop installations will generally cost less than vertical bores. For a heating-dominated residence, around 550 square feet/ton to size the unit. A coolingdominated residence would be estimated at around 450 square feet/ ton.

Geoexchanger energy is a natural resource, which can be used in conjunction with heat pumps to provide energy for heating and hot water. CO2 emissions are much lower than gas-fired boilers or electric heating systems. Geothermal heating is more expensive to install initially, than electrical or gas-fired heating systems. However it is cheaper to run, has lower maintenance costs, and is cleaner in use than other sources of heating [13-16]. The temperature of the earth under 2 m of the surface is a fairly constant 10ºC throughout the year. At a depth of about 100 m, the temperature of any water or rock is at about 12°C throughout the year. The heat stored at this depth comes largely from the sun, the earth acting as a large solar collector. For very deep wells, in excess of about 170 m, there is an added component of heat from the core of the earth. As an approximation, one can add 3°C of heat gain for every 100 m of depth drilled into the earth.

Conclusion

The direct expansion (DX) ground source heat pump (GSHP) systems have been identified as one of the best sustainable energy technologies for space heating and cooling in residential and commercial buildings. The GSHPs for building heating and cooling are extendable to more comprehensive applications and can be combined with the ground heat exchanger in foundation piles as well as seasonal thermal energy storage from solar thermal collectors. Heat pump technology can be used for heating only, or for cooling only, or be ‘reversible’ and used for heating and cooling depending on the demand. Reversible heat pumps generally have lower COPs than heating only heat pumps. They will, therefore, result in higher running costs and emissions and are not recommended as an energyefficient heating option. The GSHP system can provide 91.7% of the total heating requirement of the building and 55.3% of the domestic water-heating requirement, although only sized to meet half the design-heating load. The heat pump can operate reliably and its performance appears to be at least as good as its specification. The system has a measured annual performance factor of 3.16. The heat pump system for domestic applications could be mounted in a cupboard under the stairs and does not reduce the useful space in the house, and there are no visible signs of the installation externally (no flue, vents, etc.). The performance of the heat pump system could also be improved by eliminating unnecessary running of the integral distribution pump. It is estimated that reducing the running time of the pump, which currently runs virtually continuously, would increase the overall performance factor to 3.43. This would improve both the economic and the environmental performance of the system. More generally, there is still potential for improvement in the performance of heat pumps, and seasonal efficiencies for ground source heat pumps of 4.0 are being achieved. It is also likely the unit costs will fall as production volumes increase. By comparison, there is little scope to further improve the efficiency of gas- or oil-fired boilers.

Acknowledgments

In order to keep this page from sounding like the breathy gush of an Oscar acceptance speech, I will keep my thanks brief, and hope that any terseness is not construed as lack on my part. Indeed, I am profoundly grateful and in ways that could adequately be expressed here. I am also grateful for the good will and generosity of all the members.

Finally, I thank my family, my friends, my readers; your support, encouragement, and enthusiasm along the way was what turned this book. It is a pleasure to acknowledge, with gratitude, all those who, at different times and in different ways, have supported Cleaner and Greener Energy Technologies, Sustainable Development, and Environment. This article would not have been possible without the contributions of several people. Also, I acknowledge the International Journal of Extensive Energy Research Institute (ERI), to all of them; I wish to express my gratitude. Thanks to my wife Kawthar Abdelhai Ali for her warmth and love. Her unwavering faith in me, her intelligence, humour, spontaneity, curiosity, and wisdom added to this book and to my life.

References

- Allan ML, Philippacopoulos AJ. Ground water protection issues with geothermal heat pumps. Brookhaven National Lab.(BNL), Upton, NY (United States); 1999.[Google Scholar]

- Anandarajah A. Mechanism controlling permeability change in clays due to changes in pore fluid. J Geotech Geo environmental Eng.2003; 129(2):163-72.[Google Scholar][Crossref]

- Ashrae B. Commercial/Institutional Ground-Source Heat Pumps Engineering Manual. Atlanta: Am Soc Heat Refrig Air-Cond Eng. 1995.[Google Scholar]

- Bejan A. Shape and structure, from engineering to nature. Camb Univ. Press; 2000.[Google Scholar]

- Bergles AE. (1988). Some perspectives on enhanced heat transfer -second generation heat transfer technology. J Heat Transf,1082196.[GoogleScholar][Crossref]

- Bowman WJ, Maynes DA. Review of Micro Heat Exchanger Flow Physics, Fabrication Methods and Applications. InASME Int Mech Eng Congr Expo. 2001.[Google Scholar][Crossref]

- EPRI and NRECA, (1997). Grouting for vertical geothermal heat pump systems: Engineering design and field procedures manual. Electric Power Research Institute TR-109169, Palo Alto, CA, and National Rural Electric Cooperative Association, Arlington, VA.[Google Scholar]

- Fahlen, Per. (1997). Cost-effective heat pumps for Nordic countries, and heat pumps in cold climates. The 3rd International Conference, Acadia University, Wolfville, Canada. 1997.[Google Scholar]

- Fridleifsson IB. Status of geothermal energy amongst the world's energy sources. Geothermics. 2003;32(4-6):379-88.[Google Scholar][Crossref]

- Jo HY, Katsumi T, Benson CH, Edil TB. Hydraulic conductivity and swelling of nonprehydrated GCLs permeated with single-species salt solutions, J Geotech Geoenviron Eng.2001;127(7):557-67.[GoogleScholar]

- Kalbus E, Reinstorf F, Schirmer M. Measuring methods for groundwater–surface water interactions: a review. Hydrol Earth Syst Sci.2006 21;10(6):873-87.[Google Scholar][Crossref]

- Sanner B, Karytsas C, Mendrinos D, et al. Current status of ground source heat pumps and underground thermal energy storage in Europe. Geothermics. 2003 1;32(4-6):579-88.[Google Scholar][Crossref]

- Li J, Zhang J, Ge W, et al. Multi-scale methodology for complex systems. Chem Eng Sci. 2004;59(8-9):1687-700.[Google Scholar][Crossref]

- Luo L, Tondeur D. Multiscale optimization of flow distribution by constructal approach. China Particuology.2005;3(6):329-36.[Google Scholar][Crossref]

- Luo L, Tondeur D, Le Gall H et al. Constructal approach and multi-scale components. Appl Therm Eng.2007;27(10):170814.[GoogleScholar][Crossref]

- Luo L, Fan Y, Tondeur D. Heat exchanger: from microâ?to multiâ?scale design optimization. Int J Energy Res, 2007;25;31(13):1266-74.[Google Scholar][Crossref]