Preserving Spent Fuel Storage Capacity by Taking Credit for Burnup in Nuclear Criticality Safety Analysis: An Alternative Solution to Spent Fuel Storage Shortage

Received: 28-Feb-2018 Accepted Date: Mar 05, 2018; Published: 09-Mar-2018

Citation: Leotlela MJ. Preserving Spent Fuel Storage Capacity by Taking Credit for Burnup in Nuclear Critcality Safety Analysis: An Alternative Solution to Spent Fuel Storage Shortage. J Mod Appl Phys. 2018;2(1): 10-12.

This open-access article is distributed under the terms of the Creative Commons Attribution Non-Commercial License (CC BY-NC) (http://creativecommons.org/licenses/by-nc/4.0/), which permits reuse, distribution and reproduction of the article, provided that the original work is properly cited and the reuse is restricted to noncommercial purposes. For commercial reuse, contact reprints@pulsus.com

Introduction

Most Generation-II nuclear power reactors that were commissioned in the 1980s have accumulated a significant amount of spent fuel in their Spent Fuel Pools (SFPs), putting the continued operation of the nuclear power station at huge risk because of the shortage of storage space in the SFP. This could seriously endanger the security of the country’s energy supply and the economy because, if no alternative storage space is found, the nuclear installation could be shut down.

When fuel is irradiated in a nuclear reactor, the fuel depletion process results in the original amount of fuel – 235U and 238U in the case of UO2 – decreasing as a result of undergoing various nuclear reactions, mainly fission [1]. This decrease is a result of transmutation and/or decay, which converts the fuel into other nuclides such as decay or fission products, some of which are fissile, for example 239Pu, 240Pu, 241Pu and 242Pu etc. The continuous buildup of fissile and fertile nuclides in the reactor core adds a positive reactivity to the system, which if not accounted for in a criticality safety analysis may result in a nuclear excursion. Nuclear criticality safety analysis can follow two approaches/scenarios, fresh fuel and burnup credit approaches.

Fresh Fuel

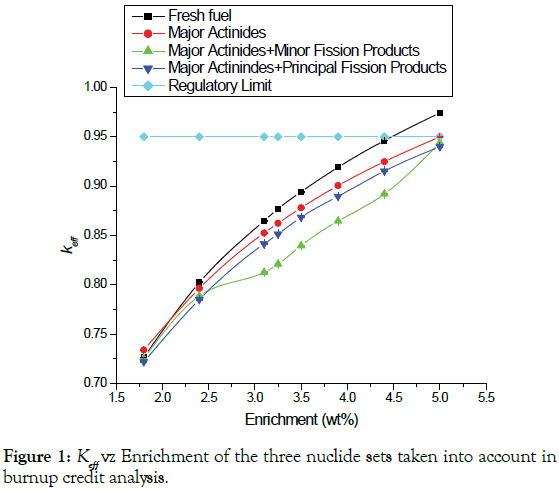

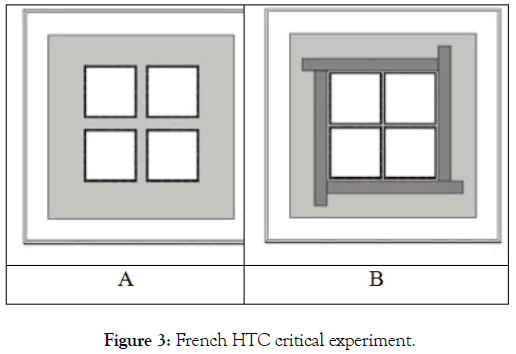

In the fresh fuel analysis scenario, it is assumed that fuel has not been irradiated, that is, it is being irradiated for the first time, which implies that other nuclides that are present in the reactor core are ignored in the analysis. There is, thus, a certain degree of conservatism built into the calculations, which often results in an over-estimation of, for example, the distance between adjacent fuel assemblies or the shielding thickness needed to prevent reactivity increasing beyond the regulatory safety margin; thus a better safety margin (Figure 1 and Figure 3) [2].

The factors that fresh fuel assumptions take into consideration when calculating criticality are the initial enrichment of the fuel, fuel temperature, moderator temperature, and fuel and moderator densities and their respective compositions. These have a direct bearing on the criticality of the system, as well as on the choice of the materials from which the cask is made and the number of fuel assemblies that can be stored in the cask [1,3].

Taking Credit for Burnup

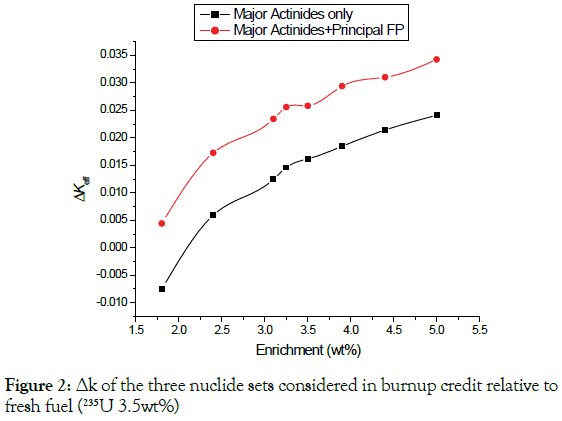

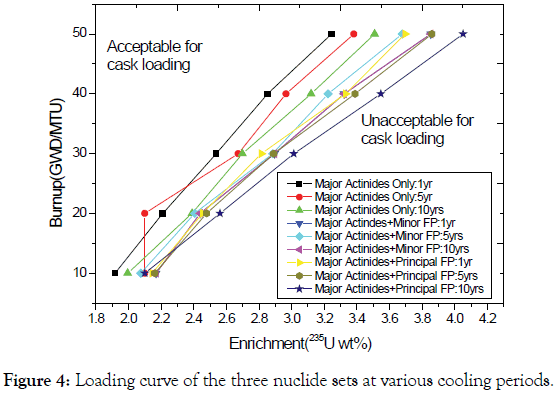

When an analysis accepts that the fuel has been in the reactor core for some time and, as a result, a number of nuclides have been generated which, when taken into account in the analysis, will result in lower keff than that of fresh fuel, that phenomenon of taking credit for the reduction in reactivity is known as burn-up credit [4]. Because of this, there will be a decrease (indicated by Δk in Figure 2) in the keff of the system relative to that of fresh fuel. The economic benefit of this is that even those enrichment levels that would have exceeded the regulatory limit of 0.95, will now be below it (Figure 1), resulting in more fuel assemblies that meet the criteria for cask loading (Figure 4) [1].

When burn-up credit is taken into account, the excess safety margin shown in Figure 3A, which is associated with a high keff as a result the overconservatism associated with the fresh fuel scenario, will not be necessary because of the decrease in keff. This will result in a thinner separation gap or a less dense shielding barrier between adjacent fuel assemblies; hence, fuel assemblies may be stored in a more densely-packed pattern, without the risk of increasing the keff, as shown in group B relative to group A of Figure 3 [5].

In many cases, the checker-board pattern used in SFPs for less reactive assemblies (e.g. spent fuel where credit for burnup is taken into account) differs from that used in highly reactive fuel assemblies, in that when credit for burnup is taken into account a close-packing storage pattern is used. This pattern, that is densely packed storage pattern, results in fewer transportation trips and a lower risk of accidents during transportation [2,5].

Further, a close-packing storage pattern will result in a thinner separation gap or less dense shielding barrier between adjacent fuel assemblies; hence, storing fuel assemblies in a more densely-packed storage pattern, without the risk of increasing the keff, as shown in group B relative to group A of Figure 3.

Because of its economic benefit in spent fuel storage, burnup credit has been studied quite extensively in the USA, and the US Nuclear Regulatory Commission (NRC) has accepted it as one of the analytical techniques that nuclear criticality safety analysis can use to save storage space [5,6].

If burnup credit (BUC) is taken into account in nuclear criticality safety analysis, as Figure 2 shows, there will be a reduction in keff relative to fresh fuel because of the build-up of nuclides with parasitic absorption of neutrons [6,7]. A similar study performed in the USA shows an increase of 11% in the number of fuel assemblies that qualify for cask loading (Figure 4).

The three nuclide sets listed below, together with their respective nuclides, have been identified as important to criticality [8-10]:

• Major Actinides Only: 234U, 235U, 238U, 238Pu, 239Pu, 240Pu, 241Pu, 242Pu and 241Am.

• Major Actinides + Minor Fission Products: 234U, 235U, 238U, 238Pu, 239Pu, 240Pu, 241Pu, 242Pu, 241Am, 243Am, 237Np, 133Cs,143Nd, 151Sm and 155Gd

• Major Actinides + Principal Fission Products: 234U, 235U, 238U, 238Pu, 239Pu, 240Pu, 241Pu, 242Pu, 241Am, 243Am, 237Np, 99Tc,133Cs, 143Nd 145Nd, 147Sm, 150Sm, 151Sm, 152Sm, 151Eu, 153Eu, 155Gd, O1.

The effect of taking the nuclides into account in criticality safety analysis is summed up in Figures 2 and 3 of ref [6]. Thus, based on this study, it is evident that taking credit for burnup often results in a significant increase in spent fuel storage space, as a result of the decrease in keff in the fissile system relative to the fresh fuel. The amount of storage space saved by taking credit for burnup has been validated experimentally at Oak Ridge National Laboratory in Tennessee (Figure 2) [11]. This allows for more spent fuel to be stored in a smaller space compared to that required for fresh fuel, without violating the regulatory sub-criticality requirement of 0.95 for safe storage of the fuel [11].

Conclusion

There is more than enough researched evidence to show that when burnup credit is taken into account in nuclear criticality safety analysis, the nuclear operator can recover the spent fuel storage space lost to the fresh fuel approach. Thus, on this basis there should be no reason to still doubt the value of burnup credit in saving spent fuel storage space.

There are a number of countries whose regulators have authorised burnup credit, but there are also many which have not. Those that do include France [12], Japan, South Korea [13] and the USA [2,5]. To that effect, the NRC issued an Interim Staff Guidance to provide guidance on the application of burnup credit whose core message is the following:

This Interim Staff Guidance (ISG) provides recommendations to the staff for accepting, on a design-specific basis, a burnup credit approach in the criticality safety analysis of pressurized water reactor (PWR) SNF storage and transportation systems. This revision to ISG-8 incorporates the results of burnup credit-related research that has been conducted since Revision 2 (Rev. 2) was published in September 2002. Based on the detailed results of this research and the technical judgment of the US Nuclear Regulatory Commission (NRC) staff, ISG-8, Rev. 3, includes two major changes in the recommendations to staff reviewing burnup credit applications for SNF transportation and storage systems:

(1) optional credit for fission product and minor actinide neutron absorbing isotopes in the SNF composition, and

(2) misload analyses and additional administrative procedures in lieu of a burnup measurement at the time of loading.

Thus, in light of the shortage of storage space in SFP, which many nuclear power stations that were commissioned in the 1980s are experiencing, it is advisable that consideration be given to taking credit for Major Actinides + Minor Fission Products nuclide sets. The results of the study summarised in [1,6] show that this nuclide set can decreases the keff quite considerably compared to the Major Actinides Only and still leaves a reasonable safety margin compared to the Major Actinides + Principal Fission Products nuclide sets. As Wagner indicated [9,10], the inclusion of fission products in burnup credit calculations will increase the number of fuel assemblies acceptable for loading from 11 to 58%. This is a significant increase in the number of fuel assemblies acceptable for loading in the casks and can buy a reactor operator a fair amount of time before running out of storage space in the SFP, while maintaining the safety margin within the regulatory limit.

Furthermore, in addition to the saving on storage space, there will also be a reduction in the number of consignments to the interim spent fuel storage installation, thus reducing the risk of nuclear-related accidents associated with transporting spent fuel to the storage facility.

REFERENCES

- Leotlela M. Criticality Safety Analysis Of The Design Of Spent Fuel Cask, Its Manipulation And Placement In A Long-Term Storage, A. Barnby, Edn, University Of the Witwatersrand, 2016.

- Wagner J, DeHart M. "Review of Axial Burnup Distribution Considerations for Burnup Calculations," Oak Ridge National Laboratory, Oak Ridge, 2000.

- Leotlela M, Olifant T, Petr I. "Time-Dependent Variation Of The Neuton Multiplication Factor In Spent Fuel Storage," Kerntechnik, 2017;82:6.

- Withee C, Carlson D. "Spent fuel burnup credit in casks: An NRC Perspective," in Proceeding of the 27th Water Reactor Safety Information meeting held in Bethesda Mariott Hotell, Bethesda, Maryland. - Maryland, 2000:419-36.

- NRC, "Interim Staff Guidance-8".

- Leotlela M. "Sensitivity analysis of parameters important to nuclear criticality safety of Castor X/28F nuclear fuel cask," Kerntechnik,2015;5(80):485-93.

- Wagner J. "Evaluation of Burnup Credit for Accommodating PWR Spent Nuclear Fuel in High-Capacity cask design," Oak Ridge National Laborator, Oak Ridge, 2006.

- Radulescu G, Gauld I. "STARBUCS: A scale control module for automated criticality safety analyses using burnup credit," Oak Ridge National Laboratory, Oak Ridge, Tennessee. 2009.

- Wagner J. "Computational Benchmark for estimation of reactivity margin from fission products and minor actinides in PWR burnup credit," Oak Ridge National Laboratory, Oak Ridge, 2001.

- Wagner J, Sanders E. "Assessment of reactivity margin and loading curves for PWR burnup credit cask designs," Oak Ridge National Laboratory, Oak Ridge, 2003.

- Parks C, Wagner J, Mueller D. "Full burnup credit in transport and storage casks: Benefits and implemetantion," in American Nuclear Society; 2006 International High-Level Radioactive Waste Management Conference, Las Vegas. 2006.

- Cousinou P, Lavarenne C, Biron D, et al. "Taking burnup Credit into account in criticality studies: the situation as it is now and prospects for the future.," Nuclear Engineering And Design. 2001;208:205-14.

- Lee SH, Ahn JG, Hwang HR. "Conceptual Cask Design with Burnup Credit," Korea Power Engineering, Daejeon.