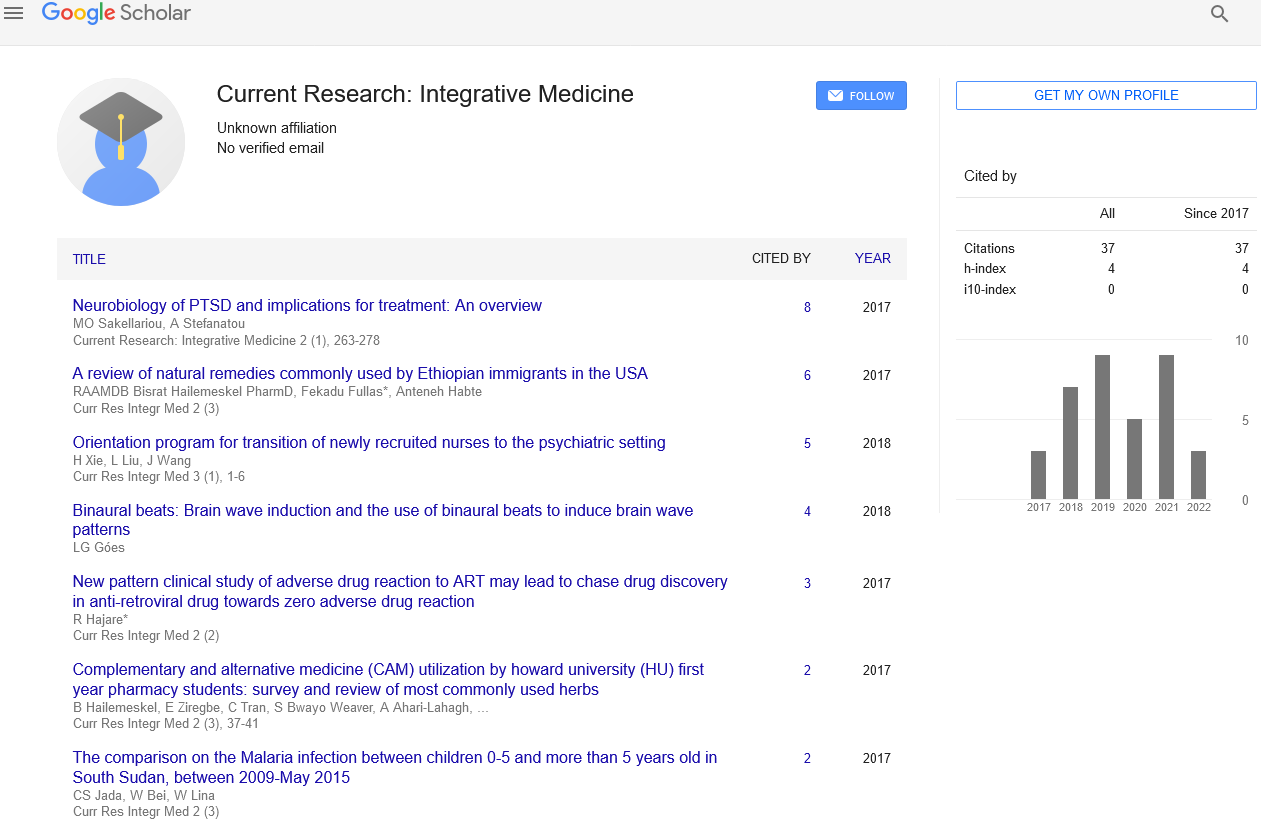

Synthesis and Drug Delivery Applications for Mesoporous Silica Nanoparticles

Received: 04-Sep-2017 Accepted Date: Oct 05, 2017; Published: 05-Oct-2017

Citation: Zhao P, Liu MC, Lin HC. et al. Yarat A, Synthesis and Drug Delivery Applications for Mesoporous Silica Nanoparticles. J Med Biotechnol 2017;1(1):1-8.

This open-access article is distributed under the terms of the Creative Commons Attribution Non-Commercial License (CC BY-NC) (http://creativecommons.org/licenses/by-nc/4.0/), which permits reuse, distribution and reproduction of the article, provided that the original work is properly cited and the reuse is restricted to noncommercial purposes. For commercial reuse, contact reprints@pulsus.com

Abstract

In the past decade, mesoporous silica nanoparticles (MSNs) have attracted increasing attention for their potential biomedical applications. With their tailored mesoporous structure and high surface area, MSNs as drug delivery systems (DDSs) show significant advantages over traditional drug nanocarriers. MSNs have the characteristics of large specific surface area and large pore volume, easy to be modified on the inner and outer surfaces, high drug loading and high targeting ability, thus showing a wide application prospect. In this paper, the influencing factors, functionalization of MSNs synthesis method and drug delivery system were introduced, and the environmental response in drug releasing were also reviewed.

Nowadays, nanoscience is considered as one of the most important research and development fields in modern science. Due to the advent of new and improved technology in recent years, research on nanotechnology, in particular, engineered nanomaterials, has received considerable attention [1]. According to the pore size of porous, nanomaterials can be divided into the following three categories, namely, microporous, mesoporous, macroporous materials. Pore diameter differences will lead to changes in the nature of the materials. The mesoporous material is a kind of inorganic or organic material with ordered pore structure and pore size of 2-50 nm [2]. Mesoporous silica materials as one of them, were intensively researched in recent decades [3-5].

Since the mesoporous silica material have excellent physicochemical characteristics such as high surface area, tunable pore size, pore volume, thermal and chemical stability, hydrophilicity, enriched surface silanol groups and easy surface modifications [6-10] to expand its scope of application. In addition, studies have shown that mesoporous silica materials also have good biocompatibility and biodegradability in animal or plant cells [11-13]. Based on the above advantages, mesoporous silica has a wide range of applications in adsorption and separation [14-17], catalysis [18-20], chromatography [21], biomedical [22-25] and many other fields. In this paper, the synthesis, structural design factors, drug transport and biological safety of the relevant progress on MSNs were reviewed.

Literature Review

The synthetic mechanism of mesoporous materials

Many mechanisms have been proposed to explain the formation of MSNs since the mesoporous material has emerged. Among the various mechanisms proposed, there is a common characteristic of the solution that the surfactant activates the solvated inorganic precursor to form a mesoporous structure. At present, the molecular lattice mechanism of the mesoporous material synthesis, is different from that of the traditional microporous molecular hoof synthesis. The mechanism is divided into the following categories that liquid crystal template mechanism, rod-like self-assembly mechanism, charge density matching mechanism and association mechanism. Most of these models believe that the surfactant in the solution directs the inorganic precursors to self-assemble.

Liquid crystal template mechanism

Liquid crystal template mechanism was first proposed by Mobile’s company [26,27]. The core of this mechanism is that the mesoporous MCM-41 is formed as a template for the liquid crystal phase formed by the surfactant. Surfactants with amphiphilic properties evolved from spherical micelles to form rod-like micelles in aqueous systems. The core of the rod-shaped micelles consisted of the hydrophobic end of the surfactant and the outer surface consisted of hydrophilic ends. When the surfactant concentration increases to a certain extent, a hexagonal ordered liquid crystal phase is formed. In this case, the monomer molecules or oligomers formed by the hydrolysis of the inorganic species in the solution interact with the hydrophilic end, and then deposited on the surface of the surfactant micelle to form a mesoporous material. The mechanism of liquid crystal template is simple and intuitive, and the concept of template is introduced in the synthesis of mesoporous materials. Therefore, this mechanism is widely accepted by researchers in the early days [26,27].

Synergistic mechanism

Synergistic mechanism is another synthetic mechanism of the mesoporous materials proposed by Mobile’s scientists. Similar to the Liquid crystal template, this mechanism also considered the liquid crystal phase of the surfactant as a template for the mesoporous material. The difference between these two mechanisms is that the synergistic mechanism considers the liquid crystal to be produced after the addition of the inorganic species. The interaction between the inorganic species and the surfactants, mainly manifests on the fact that the micelles of the organic surfactants accelerate the condensation of inorganic precursors and meanwhile the later could promote the formation of the former. The synergistic mechanism can explain the low surfactant concentration in the synthesis of mesoporous materials and the different structures between the mesostructure and the liquid crystal [28].

Cooperative self-assembly mechanism

In addition, there is a widely accepted collaborative self-assembly mechanism, which suggests that ordered mesoporous is achieved by cooperative assembly between surfactant and inorganic species. For the synthesis of mesoporous silica nanoparticles, the interactions between the cations of surfactant and anions of poly silicate leads to the polymerization of the silicate at the interface. With the process of the reaction, the charge density of the inorganic layer and the composition of the inorganic and organic species will change gradually, and the final phase is determined by the polymerization degree of the inorganic species [29].

Synthesis of Mesoporous Silica Nanoparticles

The pore silica nanoparticles have the advantages of large specific surface area, adjustable particle size and thermal stability. Currently, the synthesis of mesoporous silica materials is mainly based on the surfactant as a structuredirecting agent. The main methods are: sol-gel method [30], hydrothermal synthesis [31,32], microwave synthesis [33] and Template synthesis method [34,35]

Sol-gel method

Sol-gel method provides many favorable conditions for the synthesis of particles, such as controlled functional modification on the surface. There are two stages in the synthesis process, the first stage is the formation of particles in the solution of glue body suspension; and then, the particles form a three-dimensional network of polymer chain, the gel. General synthesis mesoporous silica template types are as follows: block copolymer template, surfactant template, floating template, machine small molecule template and so on. This sol-gel technology has the advantages such as lowtemperature environment, simple equipment easy controlled operation and high product purity [36].

Hydrothermal synthesis

The basic process of hydrothermal synthesis is using surfactants as a template agent, acid or alkali as a catalyst, and then slowly adding an inorganic substance to the mixed solution to obtain a hydrogel which is transferred to the autoclave. High temperature and high pressure are needed to deal with the reaction precursor, and the precursor are separated and organic matter is removed [37]. This synthetic method has a distinctive feature: its reaction environment is far superior to the general conditions; can completely dissolve precursor, effectively reducing the material reaction time; meanwhile, improving the hydrothermal stability of the material. Hydrothermal synthesis method also has shortcomings, such as the long reaction time and complex process. Therefore, the development of a simple and energy-saving method is needed. The new synthetic process is a challenge for current mesoporous materials

Microwave synthesis method

Microwave is a kind of electromagnetic wave (frequency 300MHZ-300GHZ). Microwave is different from the traditional heating method since it is under the action of electromagnetic field with both inside and outside heating, rapid heating speed, energy efficient and so on. The mesoporous materials were synthesized by microwave irradiation, and the whole process was less than 6 hours. Compared with the hydrothermal method, the synthesis time is greatly reduced. Obviously, the microwave technology is energysaving, time-saving and simple operation [38] Wu et al. [39] first prepared nano-mesoporous materials by microwave method. The results showed that the mesoporous silicon with ordered pore size was rapidly synthesized by microwave method, and the crystallinity was good. MCM-41 [39] MCM-48 [40], SBA-15 [41] have also been successfully synthesized using microwave radiation.

Template synthesis method

Template synthesis of surface activity in the solvent, acid or alkaline conditions to form micelles, inorganic precursors to micelles as a template slowly react, and then burn back to form mesoporous ordered materials [42-45]. There are two kinds of soft template method and hard template method. The noncovalent bond between the surface active agent and the inorganic reaction is a soft template method. The product is typically between 10 and 1000 nm. A hard template is a method of in situ preparation of a solid nanocrystal or mesoporous material, which is a template for filling an object with its pores. The range of the template pore walls is 2-50 nm of the mesopores, so that the ordered mesopores of 2-50 nm of the product after removal of the template.

Drug Delivery System

As a drug delivery system, the loading of the drug in the mesoporous silica material and the release in a given environment are two key processes. Currently, the pore size, specific surface area, pore size, pore and surface functionalization are the main factors influencing mesoporous SO2 materials on drug loading and release [46].

Pore size

For drug loading process, the ordered mesoporous silica material, which is used as the carrier, is immersed in the high concentration of the drug solution, and the drug enters the channel of the ordered mesoporous SO2 through the diffusion process. In this process, the pore size of the mesoporous silica material and the relative size of the drug to be loaded will directly affect the loading process of the drug.[47] Wright et al. investigated the adsorption of SIS-15 mesoporous urethane materials for different sizes of proteins. [48] When the pore size (5.1 nm) is larger than the protein size, the protein will be relatively easy to enter the pore of the MSNs, where the protein is mainly supported in the pore structure; and when the pore size is less than protein size, the adsorption occurs mainly on the outer surface of the MSNs. When the drug is released from the channel, the size of the pore has a significant effect on the drug release rate. Vallet-regi et al. Investigated the effect of different pore sizes on the release rate. They observed that the release rate of the IBU from the mesoporous channels decreases with decreasing mesopore size [49].

Specific surface area

Since the size of most drugs is much smaller than the pore size of the MSNs, only the drug adsorbed in the pores of the mesopore (a small amount of MSNs) can be retained by the MSNs in the channels. In this sense, the main factor affecting the drug loading of the MSNs is its specific surface area. Vallet-Regi et al. [49] loaded sodium phosphonic acid using MCM-41 with small pore size (3 nm) and larger surface area (1157 m2/g), and SBA-15 with larger pore size (9 nm) and smaller surface area (719 m2/g). The drug loading was 14% and 8% for MCM-41 and SBA-15, respectively, indicating that the larger specific surface area was beneficial to the drug loading [50]. The subsequent literature also supports this view [51,52]. Although the larger specific surface area is beneficial to increase the loading of the drug, it is also inevitably reduces the releasing rate of the drug molecules from the channel, due to the presence of more interacting sites between the drug molecules and the materials. In the above literature, the release rate of Alendronate from the MCM-41 pore shows a first-order kinetics, while the release rate from SBA-15 shows zero-order kinetics [50].

Pore volumes

The pore volume of MSNs mainly affects the loading of bulk molecules, especially proteins [53-57]. Vallet-Regi et al. used SBA-15 (pore volume 1.1 cm2/g) and mesoporous foamed silica (MCF, pore volume 1.9 cm3/g) to support bovine serum protein [57,58] and found that SBA-15 loaded BSA with an amount of 15% and MCF load of 24%. Thus, it is clear that the larger pore volume is conducive to improving the loading of the guest molecules.

Pore and surface functionalization

It is possible to further functionalize the mesoporous silica because the outer surface and the pore walls of the mesoporous SO2 material are rich in silicon hydroxyl groups. The functionalization of mesoporous silica can adjust the chemical properties of the surface of the mesoporous silica material [59], alter the pore hydrophobicity/hydrophobicity [60], acidity and pore size [61], and so on. For example, due to the strong interaction between the amino group and the carboxyl group of the IBU, the mesoporous silica material functionalized by the amino group can effectively increase the amount of loading and prolong the sustained release time. The hydrophilicity of the amino group is better than that of the silanol group. The surface modification of the mesoporous SO2 material can effectively improve the hydrophilicity of the mesoporous SO2 material, thereby improving the hydrophilicity of the amount of molecular load [62]. Although the surface functionalization of the mesoporous silica material can effectively regulate the loading of different drugs, in general, due to the strong interaction between the host and guest, the higher drug loading will reduce the drug release rate. Thus, to improve the release rate of drugs in different environments, it is the feasible improvement method to synthesize the mesoporous silica materials with certain environmental responsiveness on its surface.

Environmental Response Mesoporous Silicon Dioxide Drug Delivery System

The pores within the mesoporous materials can only play a role in slow release under normal physiological conditions, but they cannot block the drug molecules. In comparison, the modification of responsive molecules to the surface of the mesoporous material not only blocks the channels, prevents the “premature release” of the drug molecules, but also has the function of stimulating the release of the drug molecules in response to the environment. Currently, based on the mesoporous silica nanoparticles, the researchers have developed a series of controlled release systems that respond to pH [63-67], light [68-72], enzyme [73-76], redox [77-83], and temperature signals [84,85].

pH controlled release

Normal human tissue and tumor sites and other organizations have different pH values. To achieve targeted drug release and improved drug utilization, this pH difference could be applied in the drug carrier design. Zhang and his research group members successfully designed and synthesized Fe3O4/silica core/shell nanocarrier, and pH sensitive amide bond was conjugated on the particle surface. The experiment showed that these particles have a good pH response to control release performance [85]. The control release system of pH response is an intracellular self-responsive release system, which is more effective than other response systems.

Light control release

Light is an important field stimulus signal that can improve the operability of the controlled release system and is very sensitive in responding to external stimuli. Light can achieve quantitative controlled release by adjusting the light intensity and emission wavelength. The main principle is to control the light time and light area to break the chemical bond, which results in the opening of the mesoporous nanometer door. Jiang et al. have modified the carboxy-functional spiropyran on the surface of the mesoporous silica containing the drug, and the drug can be encapsulated in the channel due to the hydrophobicity of the carboxyl group. When irradiated with ultraviolet light, spiropyran structure changes, resulting in drug release to achieve the purpose of treatment [86]. However, since the developed light control system mainly responds to the optical wavelengths, it is difficult to apply to cells and the human body. Compared with ultraviolet or optical light, near-far infrared light can penetrate the cell tissue, and does not cause damage to cells and tissues, and thus the development of near-far infrared light control system is the future research direction.

Enzyme controlled release

It is well known that the metabolism of the human body and all the chemical reactions related to life activities are inseparable from the participation of enzymes. There are more than 700 kinds of enzymes needed for human life activities. The main parts are stomach, mouth, intestine, liver, pancreas with muscle and so on. Compared with other response systems, the enzymecontrolled release system is more specific, more accurate, and more suitable for human environment. Since some human disease signals are due to the abnormal increase in some enzyme indicators, the detection of these enzymes and response to the release of these enzymes have a very important clinical significance. Gil et al loaded the metal ruthenium complex in MCM-41, and the ester moiety on its pore modification was used as a “nanometer gate”. When the esterase was present, the ester bond on the group was hydrolyzed, releasing the drug while releasing the glycol [87,88].

Temperature responsiveness

Because most of the tumor tissue temperature is slightly higher than the normal temperature of the human body (40°C), the temperature-sensitive substances becomes a hot spot in the field of functional macromolecules [89,90]. Temperature responsive polymer refers to a polymer shows different properties at different temperatures. When the temperature of the polymer is raised to a certain temperature, its solubility will be reduced. This temperature is called the lowest critical solution temperature (LCST) [90]. Among them, polyisopropyl acrylamide (PNIPAM) is the most commonly used a thermosensitive polymer, the LCST is 32, which is close to the body temperature. Baeza A et al. [91] modified the temperature-sensitive polymer PEI/NIPAM onto the surface of the loaded iron oxide and silica core shells to prepare a temperature-responsive drug delivery system. When the system was in the alternating magnetic field, the resulting magnetic heat causes the temperature-sensitive polymer to phase change and release the drug.

Redox responsiveness

The redox-responsive MSNs drug delivery system is typically prepared by introducing disulfide bonds into the synthesis, using organic molecules or inorganic nanoparticles for nanoser. When adding a reducing agent such as dithiothreitol glutathione, the disulfide bond will be disconnected. The drug molecules are thus released from the opened mesopores.

Lai et al. [92] controlled the release of drug molecules and neurotransmitters by immobilizing CdS nanoparticles on the surface of the mesoporous silicon as a moveable “cap”. Vancomycin and adenosine triphosphate (ATP) were loaded in the MSN delivery system. In vitro experiments showed that when the system is in the dithiothreitol (DTT) or mercaptoethanol (ME) and other reductase environment, disulfide bonds broken, resulting in the release of drugs from the pore size.

Discussion

In addition to the above-mentioned response control release, some other controlled releases were researched, such as magnetic materials, DNA, chemical substances and other signals of a series of controlled release system. Meanwhile, researchers have designed a series of controlled release systems that respond to a variety of environmental stimuli. With the study of the controlled release system of mesoporous silica, the researchers prepared composite mesoporous silica nanostructures by introducing other nanomaterials. A series of controlled release, targeted transport and photodynamic binding were prepared, namely muti-functional MSNs delivery system. We will discuss this in other review.

Conclusion and Outlook

The hole material, due to its unique performance, has shown great application in various fields. The drug delivery system based on mesoporous silica can be precisely controlled in terms of size structure and the results of targeted transmission. Controlled release drug and multi-functional development have also yielded fruitful results. For example, multifunctional nanocomposites that respond with light, electricity, heat, and magnetic activity in combination with photodynamic therapy have been developed. However, for further practical application, attention should be paid to the following aspects: the release of the behavior is single; some special functionalized MSNs have toxicity to normal physiological behavior of cells and organisms; precise and efficient drug-controlled release remains to be explored. Although there are many problems not resolved, but it is believed that these problems will be gradually overcome and MSNs will be more efficient in diseases diagnosis and treatment.

REFERENCES

- Abbasi AN, Islamian JP, Hatamian M, et al. Doxorubicin loaded large-pore mesoporous hydroxyapatite coated superparamagnetic Fe3O4 nanoparticles for cancer treatment. Int J Pharma. 2016;509:159-67.

- Wu SH, Mou CY, Lin HP. Synthesis of mesoporous silica nanoparticles. Chem Soc Re.v 2013;42:3862-75.

- Renzo FD, Cambon H, Dutartre R. A 28-year-old synthesis of micelle-templated mesoporous silica. Micropor Mat. 1997;10:283-286.

- Kresge CT, Leonowicz ME, Roth WJ, et al. Ordered mesoporous molecular sieves synthesized by a liquid-crystal template mechanism. Nature. 1992;359:710-12.

- Beck JS, Vartuli JC, Roth WJ, et al. A new family of mesoporous molecular sieves prepared with liquid crystal templates. J Am Chem Soc. 1992;114:10834-43.

- Derrick T, Ashley CE, Min X, et al. Mesoporous silica nanoparticle nanocarriers: biofunctionality and biocompatibility. Accounts Chem Res. 2013;46:792-801.

- Slowing II, Trewyn BG, Lin VS. Mesoporous silica nanoparticles for intracellular delivery of membrane-impermeable proteins. J Am Chem Soc. 2007;129:8845-49.

- Tu J, Boyle AL, Friedrich H, et al. Mesoporous silica nanoparticles with large pores for the encapsulation and release of proteins. Acs Appl Mater Inter. 2016;8:32211-19.

- Xu C, Yu M, Noonan O, et al. Core-cone structured monodispersed mesoporous silica nanoparticles with ultra-large cavity for protein delivery. Small. 2016;11:5949-55.

- Clemments AM, Botella P, Landry CC. Spatial mapping of protein adsorption on mesoporous silica nanoparticles by stochastic optical reconstruction microscopy. J Am Chem Soc. 2017;196:3978-81.

- He Q, Shi J, Zhu M, et al. The three-stage in vitro degradation behavior of mesoporous silica in simulated body fluid. Micropor Mesopor Mat. 2010;131:314-20.

- He Q, Zhang Z, Gao F, et al. In vivo biodistribution and urinary excretion of mesoporous silica nanoparticles: effects of particle size and PEGylation. Small. 2011;7:271-80.

- Chen G, Teng Z, Su X, et al. Unique biological degradation behavior of stöber msesoporous silica nanoparticles from their interiors to their exteriors. J Biomed Nanotechn. 2015;11:722-29.

- Shinde P, Gupta SS, Singh B, et al. Amphi-functional mesoporous silica nanoparticles for dye separation. J Mater Chem A. 2017;5:14914-21.

- Sheng W, Wei W, Li J, et al. Amine-functionalized magnetic mesoporous silica nanoparticles for DNA separation. Appl Surf Sci. 2016;387:1116-24.

- Beck M, Mandal T, Buske C, et al. Serum protein adsorption enhances active leukemia stem cell targeting of mesoporous silica nanoparticles. ACS Appl Mater Inter. 2017;9:18566-74.

- Sun Y, Li J, Wang Y, et al. A chemiluminescence biosensor based on the adsorption recognition function between Fe3O4@SiO2@GO polymers and DNA for ultrasensitive detection of DNA. Spectrochim Acta A. 2017;178:1-7.

- Munz D, Wang D, Moyer MM, et al. Aerobic epoxidation of olefin by platinum catalysts supported on mesoporous silica nanoparticles. Acs Catal. 2016;6:4584-93.

- Collins G, Rahme K, O'Connell J, et al. Embedding colloidal nanoparticles inside mesoporous silica using gas expanded liquids for high loading recyclable catalysts. Catal Sci Technol. 2016;6:7212-19.

- Tang D, Zhang W, Qiao Z, et al. Functionalized mesoporous silica nanoparticles as a catalyst to synthesize a luminescent polymer/silica nanocomposite. Rsc Adv. 2016;6:16461-66.

- Kim DJ, Chung JS, Ahn WS, et al. Morphology control of organic–inorganic hybrid mesoporous silica by microwave heating. Chem Lett. 2009;33:422-3.

- Chen Y, Li Z, Qin J, et al. Monodispersed mesoporous silica (mSiO2) spheres as abrasives for improved chemical mechanical planarization performance. J Mater Sci. 2016;51:5811-22.

- Yu X, Zhu Y. Preparation of magnetic mesoporous silica nanoparticles as a multifunctional platform for potential drug delivery and hyperthermia. Sci Technol Adv Mat. 2016;17:229-38.

- Chen Y, Chen HR, Shi JL. Construction of homogenous/heterogeneous hollow mesoporous silica nanostructures by silica-etching chemistry: principles, synthesis, and applications. Accouts Chem Res. 2014;47:125-37.

- Du X, Li X, Xiong L, et al. Mesoporous silica nanoparticles with organo-bridged silsesquioxane framework as innovative platforms for bioimaging and therapeutic agent delivery. Biomaterials. 2016;91:90-127.

- Beck JS, Vartuli JC, Roth WJ, et al. A new family of mesoporous molecular sieves prepared with liquid crystal templates. J Am Cheml Soc. 2016;114:10834-43.

- Vartuli JC, Schmitt KD, Kresge CT, et al. Development of a formation mechanism for M41S materials. Stud Surf Sci Catal. 1994;84:53-60.

- Huo Q, Margolese DI, Ciesla U, et al. Generalized synthesis of periodic surfactant/inorganic composite materials. Nature. 1994;368:317-21.

- Keshavarz M, Ahmad N. Characterization and modification of mesoporous silica nanoparticles prepared by sol-gel. J Nanopart. 2013;4:115-21.

- Loryuenyong V, Muanghom T, Apinyanukul T, et al. Synthesis of templated mesoporous silica nanoparticles under base catalysis. Adv Appl Ceram. 2011;110:335-339.

- Gu L, Zhang A, Hou K, et al. One-pot hydrothermal synthesis of mesoporous silica nanoparticles using formaldehyde as growth suppressant. Micropor Mesopor Mater. 2012;152:9-15.

- Meynen V, Cool P, Vansant EF. Verified syntheses of mesoporous materials. Micropor Mesopor Mater. 2009;125:170-223.

- Abd. Jalil A. Utilization of microwave for the synthesis of mesoporous silica nanoparticles as ibuprofen drug delivery vehicles Injury. 2014;45:1185–9.

- Li M, Liu N, Wu Z, et al. A facile and novel route for dual-template method synthesis of mesoporous silica material Al-Ce-SBA-15. Mater Lett. 2016;185:85-8.

- Kumar S, Malik MM, Purohit R. Synthesis methods of mesoporous silica materials. Mater Today. 2017;4:350–7.

- Ge NL, Zhang D, Wei HB, et al. Bifunctional ionic liquid as template in the preparation of mesoporous silica via a sol-gel method. J Func Mater. 2014;45:20068-73.

- Tomer VK, Malik R, Jangra S, et al. One pot direct synthesis of mesoporous SnO2/SBA-15 nanocomposite by the hydrothermal method. Mater Lett. 2014;132:228-30.

- Bian S. Organic/inorganichybrid mesoporous silica membrane rapidly synthesized by a microwave-assisted method and its application in enzyme adsorption and electrocatalysis. J Mater Chem B. 2013;1:3267-76.

- Wu CG, Bein T. Microwave synthesis of molecular sieve MCM-41. Chem Commun. 1996;28:925-30.

- Pasqua L, Procopio A, Oliverio M, et al. Hybrid MCM-41 grafted by a general microwave-assisted procedure: a characterization study. J Porous Mat .2013;20:865-73.

- Celer EB, Mietek J. Temperature-programmed microwave-assisted synthesis of SBA-15 ordered mesoporous silica. J Am Chem Soc. 2006;128:14408-14.

- Dement eva OV, Senchikhin IN, Kartseva ME, et al. A new method for loading mesoporous silica nanoparticles with drugs: Sol–gel synthesis using drug micelles as a template. Colloid J. 2016;78:586-95.

- Li X, Shi B, Chaikittisilp W, et al. A general method to synthesize a family of mesoporous silica nanoparticles less than 100 nm and their applications in anti-reflective/fogging coating. J Mater Sci. 2016;51: 6192-206.

- Cruz P, Pérez Y, Hierro ID. Titanium alkoxides immobilized on magnetic mesoporous silica nanoparticles and their characterization by solid state voltammetry techniques: Application in ring opening polymerization. Micropor Mesopor Mater. 2017;240:227-35.

- Wu XJ, Xu D. Soft template synthesis of yolk/silica shell particles. Adv Mater. 2010;22:1516-20.

- Manzano M, Valletregí M. New developments in ordered mesoporous materials for drug delivery. J Mater Chem. 2010;20:5593-604.

- Colilla M, Manzano M, Valletregí M. Recent advances in ceramic implants as drug delivery systems for biomedical applications. Int J Nanomed. 2008;3:403-14.

- Yiu HP, Botting CH, Botting NP, et al. Size selective protein adsorption on thiol-functionalised SBA-15 mesoporous molecular sieve. Phy Chem Chem Phys. 2001;3:2983-85.

- Horcajada P, Rámila A, Pérez-Pariente J, et al. Influence of pore size of MCM-41 matrices on drug delivery rate. Micropor Mesopor Mater. 2004;68:105-9.

- Balas F, Manzano M, Horcajada P, et al. Confinement and controlled release of bisphosphonates on ordered mesoporous silica-based materials. J Am Chem Soc. 2006;128:8116-7.

- Qu F, Zhu G, Huang S, et al. Controlled release of Captopril by regulating the pore size and morphology of ordered mesoporous silica. Micropor Mesopor Mater. 2006;92:1-9.

- Vallet-Regí M. Ordered mesoporous materials in the context of drug delivery systems and bone tissue engineering. Chem-Eur J. 2006;12: 5934-43.

- Tu J, Boyle A L, Friedrich H, et al. Mesoporous Silica Nanoparticles with Large Pores for the Encapsulation and Release of Proteins. Acs Appl Mater Inter. 2016;8:32211-19.

- Malfanti A, Miletto I, Bottinelli E, et al. Delivery of Gemcitabine Prodrugs Employing Mesoporous Silica Nanoparticles. Molecules. 2016;21:522-36.

- Rijt SH, Bölükbas DA, Argyo C, et al. Applicability of avidin protein coated mesoporous silica nanoparticles as drug carriers in the lung. Nanoscale. 2016;8:8058-69.

- Beck M, Mandal T, Buske C, et al. Serum Protein Adsorption Enhances Active Leukemia Stem Cell Targeting of Mesoporous Silica Nanoparticles. Acs Appl Mater Inter. 2017;9:18566-74

- Colilla M, Balas F, Manzano M, et al. Novel method to synthesize ordered mesoporous silica with high surface areas. Solid State Sci. 2008;10:408-15.

- Sun S, Zhang X, Han Q, et al. Preparation and retention mechanism exploration of mesostructured cellular foam silica as stationary phase for high performance liquid chromatography. Talanta. 2016;149:187-93.

- Hoffmann F, Cornelius M, Morell J, et al. Silica-based mesoporous organic-inorganic hybrid materials. Angew Chem Int Edit. 2010;45:3216-51.

- Menaa, Bouzid, Torres, et al. Protein adsorption onto organically modified silica glass leads to a different structure than Sol-Gel encapsulation. Biophys J. 2008;95:51-3.

- Hata H, Saeki S, Kimura T, et al. Adsorption of taxol into ordered mesoporous silicas with various pore dameters. Chem Mater. 1999;11:1110-19.

- Duo Y, Li Y, Chen C, et al. DOX-loaded pH-sensitive mesoporous silica nanoparticles coated with PDA and PEG induce pro-death autophagy in breast cancer. Rsc Adv 2017;7:39641-50.

- Guha A, Biswas N, Bhattacharjee K, et al. In vitro evaluation of pH responsive doxazosin loaded mesoporous silica nanoparticles: a smart approach in drug delivery. Curr Drug Deliv 2016;13:574-81.

- Danfeng C, Yongfeng G, Lijun W, et al. Polydopamine-based surface modification of mesoporous silica nanoparticles as pH-sensitive drug delivery vehicles for cancer therapy. J Colloid Interf Sci 2016;463:279-87.

- Yang H, Chen Y, Chen Z, et al. Chemo-photodynamic combined gene therapy and dual-modal cancer imaging achieved by pH-responsive alginate/chitosan multilayer-modified magnetic mesoporous silica nanocomposites. Biomater Sci 2017;5:1001-13.

- Wang J, Lan J, Li H, et al. Fabrication of diverse pH-sensitive functional mesoporous silica for selective removal or depletion of highly abundant proteins from biological samples. Talanta. 2017;162:380-9.

- Yang G, Sun X, Liu J, et al. Light-responsive, singlet-oxygen-triggered on-demand drug release from photosensitizer-doped mesoporous silica nanorods for cancer combination therapy. Adv Func Mater. 2016;26:4722-32.

- Wang G, Dong J, Yuan T, et al. Visible light and pH responsive polymer-coated mesoporous silica nanohybrids for controlled release. Macromol Biosci. 2016;16:990-4.

- Huang L, Liu M, Mao L, et al. Preparation and controlled drug delivery applications of mesoporous silica polymer nanocomposites through the visible light induced surface-initiated ATRP. Appl Surf Sci. 2017;412:571-7.

- Karimi M, Mirshekari H, Aliakbari M, et al. Smart mesoporous silica nanoparticles for controlled-release drug delivery. Nanotechnol Rev. 2016;5:195-207.

- Lei Q, Qiu WX, Hu JJ, et al. Multifunctional Mesoporous Silica Nanoparticles with Thermal-Responsive Gatekeeper for NIR Light-Triggered Chemo/Photothermal-Therapy. Small. 2016;12:4286-98.

- Llopis-Lorente A, Díez P, De lTC, et al. Enzyme-Controlled Nanodevice for Acetylcholine-Triggered Cargo Delivery Based on Janus Au-Mesoporous Silica Nanoparticles. Chem-Eur J. 2017;23:4276-81.

- Kumar B, Kulanthaivel S, Mondal A, et al. Mesoporous silica nanoparticle based enzyme responsive system for colon specific drug delivery through Guar Gum Capping. Colloid Surface B. 2017;150:352-61.

- Tukappa A, Ultimo A, De lTC, et al. Polyglutamic acid-gated mesoporous silica Nanoparticles for enzyme-controlled drug delivery. Langmuir. 2016;32:8507-15.

- Gayam SR, Venkatesan P, Sung YM, et al. An NAD(P)H:quinone oxidoreductase 1 (NQO1) enzyme responsive nanocarrier based on mesoporous silica nanoparticles for tumor targeted drug delivery in vitro and in vivo. Nanoscale. 2016;8:12307-17.

- Xiao D, Hu JJ, Zhu JY, et al. A redox-responsive mesoporous silica nanoparticle with a therapeutic peptide shell for tumor targeting synergistic therapy. Nanoscale. 2016;8:16702-9.

- Alvarez-Berrios MP, Vivero-Escoto JL. In vitro evaluation of folic acid-conjugated redox-responsive mesoporous silica nanoparticles for the delivery of cisplatin. Int J Nanomed. 2016;11:6251-65.

- Qu H, Yang L, Yu J, et al. A redox responsive controlled release system using mesoporous silica nanoparticles capped with Au nanoparticles. Rsc Adv. 2017;7:35704-10.

- Chen L, Zhou X, Nie W, et al. Multifunctional Redox-Responsive Mesoporous Silica Nanoparticles for Efficient Targeting Drug Delivery and Magnetic Resonance Imaging. Acs Appl Mater Inter. 2016;8:33829-41.

- Park K, Park SS, Yun YH, et al. Mesoporous silica nanoparticles functionalized with a redox-responsive biopolymer. J Porous Mat. 2017;24:1215-25.

- Zhao S, Xu M, Cao C, et al. A redox-responsive strategy using mesoporous silica nanoparticles for co-delivery of siRNA and doxorubicin. J Mate Chem B. 2017;5:6908-19.

- Lin JT, Liu ZK, Zhu QL, et al. Redox-responsive nanocarriers for drug and gene co-delivery based on chitosan derivatives modified mesoporous silica nanoparticles. Colloids Surfaces B. 2017;155:41-50.

- Jin X, Wang Q, Sun J, et al. Dual (pH- and temperature-) stimuli responsive nanocarrier with bimodal mesoporous silica nanoparticles core and copolymer shell for controlled ibuprofen-releasing: Fractal feature and diffusion mechanism. Micropor Mesopor Mater. 2017;243:1-9

- Trewyn BG, Lin VSY. Morphological control of room-temperature Ionic liquid templated mesoporous silica nanoparticles for controlled release of antibacterial agents. Nano Lett. 2004;4:2139-43.

- Chen, Zhang LM, Chen QT, et al. Synthesis of a novel magnetic drug delivery system composed of doxorubicin-conjugated Fe3O4 nanoparticle cores and a PEG-functionalized porous silica shell. Chem Commun. 2010;46:8633-35

- Chen L, Wang W, Su B, et al. A light-responsive release platform by controlling the wetting behavior of hydrophobic surface. ACS Nano. 2014;8:744-51

- Agostini A, Mondragón L, Pascual L, et.al. Design of enzyme-mediated controlled release systems based on silica mesoporous supports capped with ester-glycol groups. Langmuir. 2012;28:14766-76

- Bo-Shi T, Chun Y. Thermo-sensitive poly (N-isopropylacrylamide)/mesoporous silica nanocomposites as controlled delivery carriers: loading and release behaviors for drug ibuprofen. J Nanosci Nanotechno. 2011; 11:1871-9.

- Baeza A, Guisasola E, Ruiz-Hernández E, et al. Magnetically triggered multidrug release by hybrid mesoporous silica nanoparticles. Chem Mater. 2012, 24:517-24.

- Chaterji S, Kwon IK, Park K. Smart polymeric gels: Redefining the limits of biomedical devices. Prog Polym Sci. 2007;32:1083-22.

- Lai CY, Trewyn BG, Jeftinija DM, et al. A mesoporous silica nanosphere-based carrier system with chemically removable CdS nanoparticle caps for stimuli-responsive controlled release of neurotransmitters and drug molecules. J Am Chem Soc. 2003;125:4451-9.

- Soler-Illia A, Crepaldi EL, Grosso D, et al. Block copolymer-templated mesoporous oxides. Curr Opin Colloid In. 2003;8:109-26.