Page 27

Volume 02

Stem Cells 2019 & Pediatrics Congress 2019

November 06-07, 2019

Journal of Clinical Genetics and Genomics

November 06-07, 2019 | Tokyo, Japan

STEM CELLS AND REGENERATIVE MEDICINE

PEDIATRICS AND CHILD CARE

International Conference on

2

nd

World Congress on

&

J Clin Gen Genomics, Volume 02

The effect of surface modification on adhesive strength between 3-D printed titanium

alloy and bone cement in orthopedic application

Magda Dziaduszewska

Gdansk University of Technology, Poland

Statement of the Problem

: A properly prepared surface plays a vital role in the successful application of various biomedical

solutions. In case of revision surgery, it is advisable to use the spacer as a temporary implant, usually made of metal rod covered

by antibiotic-loaded bone cement, used for the local treatment of postoperative infection. One of the main limitations of spacers

is their aseptic loosening, caused, i.e. by debonding effect at the metal–bone cement interface. In numerous studies it has been

suggested that implant-cement fixation properties might be improved by the appropriate manufacturing method, material

selection, as well as surface treatment of spacers.

The Purpose of this study

: In this study the effect of the surface treatment of Ti13Zr13Nb specimens produced by selective laser

melting (SLM) on bone cement coating adhesion was evaluated.

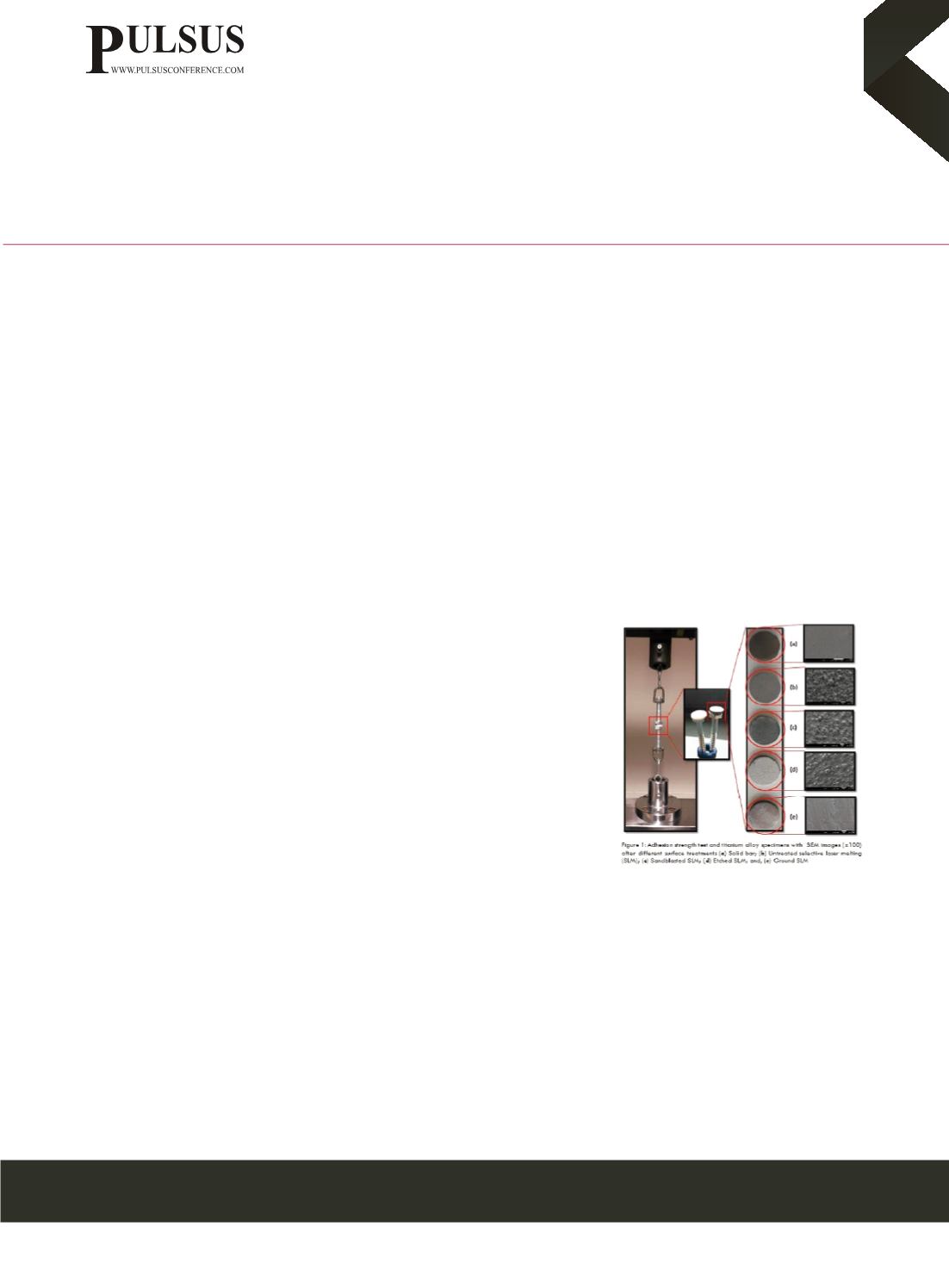

Methodology & Theoretical Orientation

: Ti13Zr13Nb alloy specimens were manufactured by selective laser melting (SLM)

method and subjected to the following surface treatments: sandblasting, grinding and

etching. Subsequently, the printed specimens were covered by bone cement. For each

condition, the surface evaluation of titanium alloy specimens, as well as the assessment

of cement adhesion to the surface, was carried out. The results of each test were

compared to the two control groups, consisting of commercially available Ti13Zr13Nb

and untreated SLM-made specimens.

Conclusion & Significance

: Surface treatment and method of fabrication of titanium

affected surface parameters that had a significant impact on cement-titanium fixation.

The highest adhesion bone cement to the titanium alloy was obtained for specimens

with high nanohardness and roughness. Sandblasting or etching were the best alloys

treatments in terms of the adhesion. Overall, the higher adhesion strength of bone

cement coating to the SLM specimens is a good precondition for the SLM application

in the production of metal-polymer implants for tissues with heavy loads.

Biography

Magda Dziaduszewska, PhD student and research assistant at the Gdansk University of Technology, Department of Materials

Engineering and Bonding, Biomaterials Division. Her main interests are connected with development and surface modification of

porous titanium structures for orthopedic applications, including selective laser melting manufacturing of scaffolds or titanium implants

with the porous surface layer, surface modification as well as the development of bioactive and biocompatible coatings.

magda.dziaduszewska@pg.gda.pl